Description

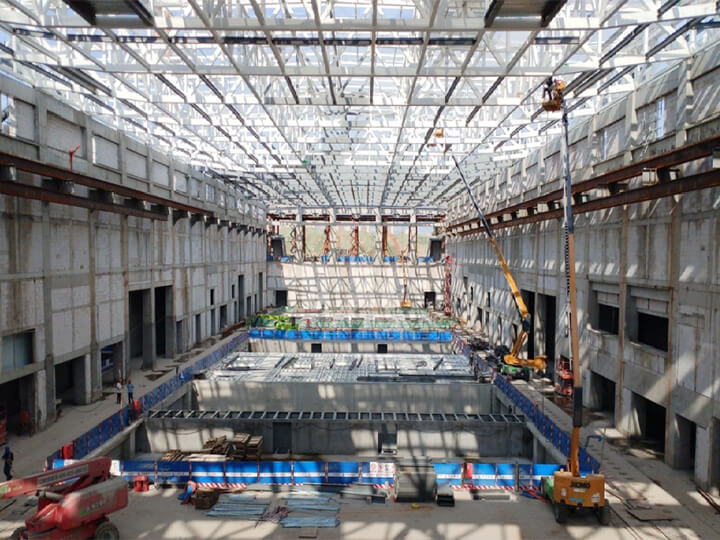

Steel structure workshops represent a cutting-edge building solution widely adopted in industrial, manufacturing, and logistics sectors worldwide. Characterized by high strength-to-weight ratio, rapid construction, and exceptional adaptability, these workshops leverage premium structural steel (e.g., Q235B, Q355B) as the primary material, complemented by advanced fabrication and assembly technologies. Unlike traditional concrete or brick structures, steel workshops offer unparalleled flexibility in design and functionality, making them the preferred choice for modern enterprises seeking cost-effective, sustainable, and future-proof industrial spaces.

1

Core Advantages

Steel’s inherent strength enables spans of up to 60 meters without intermediate columns, maximizing usable floor space. It exhibits excellent resistance to wind (up to 12-level), seismic activity (seismic intensity 7-9 degrees), and corrosion (via hot-dip galvanizing or anti-rust painting), ensuring a service life of 50+ years.

Prefabricated components are manufactured in factories with precision (tolerance ±2mm) and assembled on-site in weeks—50-70% faster than concrete structures. This minimizes construction waste, reduces labor costs, and accelerates project delivery, allowing businesses to start operations sooner.

Modular design supports easy customization of dimensions (length, width, height) and configurations (single-span, multi-span, gable or portal frame). Future expansion (e.g., adding mezzanines, extending bays) can be completed without disrupting existing operations, adapting to growing production needs.

Lower transportation costs (lightweight components), reduced maintenance requirements, and energy-efficient insulation (EPS sandwich panels, rock wool insulation) translate to long-term savings. Steel is also 100% recyclable, aligning with green building standards and reducing environmental impact.

3

Design & Quality Assurance

Our steel structure workshops adhere to international standards such as AISC (American Institute of Steel Construction), EN 1090 (European), and GB 50017 (Chinese). Key quality control measures include:

Computer-aided design (CAD) and BIM modeling for precise structural analysis.

Factory inspection of raw materials and prefabricated components (non-destructive testing for welds).

On-site supervision during assembly to ensure compliance with design drawings.

Post-construction load testing and certification for safety and durability.

4

Sustainable & Energy-Efficient Features

- Recyclability: 100% of steel components can be reused or recycled, reducing carbon footprint.

- Energy Savings: High-performance insulation materials lower heating/cooling costs by 30-40% compared to traditional structures.

- Low Environmental Impact: Minimal on-site construction reduces noise, dust, and soil disturbance.

- Solar Compatibility: Roof structures are designed to support solar panel installations, enabling renewable energy use.