Description

The Perfect Combination of Strength, Comfort and Modern Aesthetics

In the realm of modern residential architecture, steel structure villas have emerged as a pioneering choice, redefining people’s perceptions of high-quality living with their outstanding performance, flexible design, and environmental friendliness. Diverging from traditional concrete or brick-and-mortar buildings, these villas take high-strength steel as their core structural material, integrating durability, functionality, and aesthetic appeal to create a living space that meets the diverse needs of contemporary families.

1

Unmatched Structural Strength: The Foundation of Safe Living

The most prominent advantage of steel structure villas lies in their exceptional structural stability and load – bearing capacity. High – strength steel components, processed with precision, possess excellent tensile and compressive strength, enabling the villa to withstand various extreme natural conditions. Whether it is a violent earthquake, a fierce typhoon, or heavy snow accumulation, the steel structure can maintain its integrity without deformation or collapse, providing the most reliable safety guarantee for the residents.

Compared with traditional structures, steel components have uniform material properties and are not prone to problems such as cracking or aging. The connection between components adopts advanced technologies such as bolt connection and welding, ensuring the overall rigidity of the structure. This kind of structural reliability not only extends the service life of the villa (generally reaching 70 – 100 years, far exceeding that of ordinary buildings) but also reduces the maintenance costs in the later period.

This configuration uses galvanized light steel as the frame (typically Q235 or Q355 steel) and polyurethane sandwich panels as the enclosure material, forming a lightweight yet sturdy structure. The steel frame, with a compressive strength of 235-345MPa, provides reliable support while keeping the overall weight low—reducing foundation load by 40% compared to concrete sheds . The composite panels, with a thermal conductivity of only 0.022-0.026 W/(m·K), effectively insulate the interior: in cold northern regions, the shed temperature can be maintained at 10-15°C in winter without excessive heating, while in hot southern areas, the heat insulation effect reduces indoor temperatures by 5-8°C . A standard 60m×10m shed for 100 beef cattle can be assembled in just 7-10 days, with the middle 1.5m-wide passage ensuring smooth movement of feeding vehicles and staff .

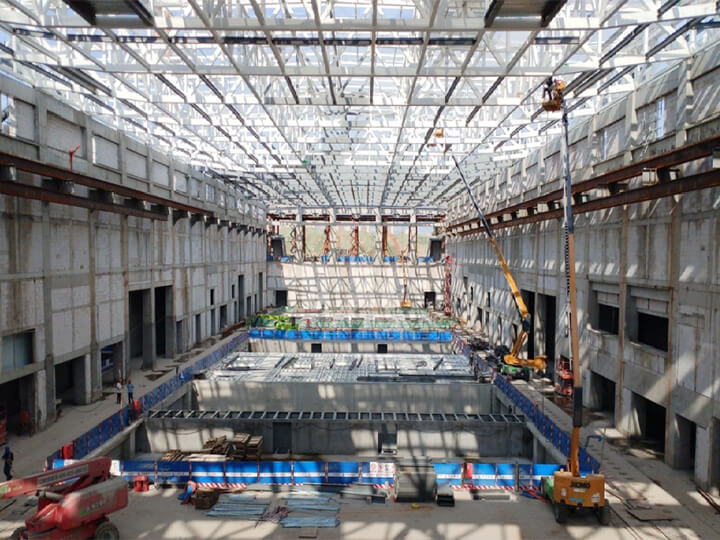

Ideal for large-scale farms with 500+ cattle, this structure uses H-steel trusses to achieve a single span of 15-20 meters without intermediate columns, maximizing usable space . The open layout facilitates the installation of automated equipment such as overhead feeding conveyors, manure scrapers, and milking machine tracks. For example, a 100m×20m dairy cattle shed can accommodate 300 milking cows with dedicated zones for feeding, resting, and milking, while the 4.5m ridge height ensures sufficient ventilation and avoids moisture accumulation . The steel trusses are treated with hot-dip galvanization, forming a 50-80μm anti-corrosion layer that resists corrosion from cattle urine and manure, extending the service life to over 20 years .

2

Flexible Design: Customize Your Ideal Living Space

Steel structure villas break the limitations of traditional building forms and offer unprecedented design flexibility. Due to the high strength – to – weight ratio of steel, the structural components are smaller in size, which greatly reduces the occupied space of load – bearing walls. This means that the internal space of the villa can be divided freely according to the owner’s living habits and functional needs.

Whether you want an open – plan living room and dining area, a multi – functional study, or a spacious master suite with a walk – in closet, the steel structure can easily realize these design concepts. Moreover, the light weight of the steel structure also reduces the requirements for the foundation, making it suitable for various terrain conditions, such as hillsides, wetlands, and other areas where traditional buildings are difficult to construct. This flexibility allows architects to give full play to their creativity, and each steel structure villa can become a unique work of art.

3

Efficient Construction: Enjoy Your New Home in the Shortest Time

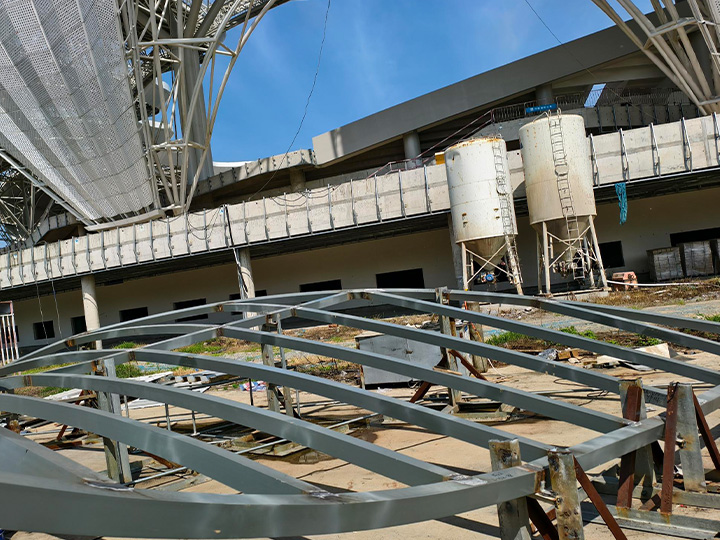

In the context of the accelerated pace of modern life, the efficient construction of steel structure villas has become a major highlight favored by owners. The main components of the steel structure are pre – processed in the factory with standardized production lines, and the processing accuracy can be controlled within a very small range. After the components are transported to the construction site, they only need to be assembled according to the design drawings, which greatly shortens the on – site construction period.

Generally speaking, the construction period of a steel structure villa with a construction area of 200 – 300 square meters is only 2 – 3 months, which is 1/3 to 1/2 shorter than that of a traditional concrete villa. At the same time, the on – site construction of the steel structure generates little noise, dust, and construction waste, which minimizes the impact on the surrounding environment and neighbors, achieving a “green construction” model.

4

Superior Living Experience: Comfort and Environmental Protection Go Hand in Hand

Steel structure villas not only have excellent structural performance but also create a more comfortable living environment for residents. The thermal conductivity of steel is relatively high, but through scientific thermal insulation design (such as filling thermal insulation materials between steel components and laying thermal insulation layers on the roof and exterior walls), the thermal insulation performance of the villa can far exceed the national standard. In winter, it can effectively retain indoor heat, and in summer, it can isolate external high temperatures, reducing the energy consumption of air conditioning and heating, and achieving energy conservation and emission reduction.

In addition, steel is a 100% recyclable material, and the recycling rate of steel components after the demolition of the villa can reach more than 90%, which avoids the waste of resources and environmental pollution caused by traditional building waste. At the same time, the production process of modern steel is constantly optimizing, and the emission of pollutants is strictly controlled, making steel structure villas a typical representative of environmentally friendly buildings.

5

Modern Aesthetics: Integrate with Nature and Life

Steel structure villas also excel in aesthetic expression. The simple and smooth lines of steel components can be perfectly integrated with various architectural styles, whether it is a minimalist modern style, a natural and comfortable rural style, or a noble and elegant European style. The large – span design of the steel structure also allows the villa to be equipped with large – area floor – to – ceiling windows, which not only increases the indoor lighting and ventilation but also connects the indoor space with the outdoor garden, lawn, and other natural landscapes, allowing residents to enjoy the beauty of nature without going out.

6

Conclusion

Steel structure villas represent the development trend of modern residential buildings. With their advantages of safety and durability, flexible design, efficient construction, comfortable living, and environmental protection, they have become the first choice for more and more families pursuing high – quality life. Whether it is the pursuit of living safety, the customization of living space, or the concern for the environment, steel structure villas can give a satisfactory answer, creating a warm, comfortable, and sustainable home for people.