Description

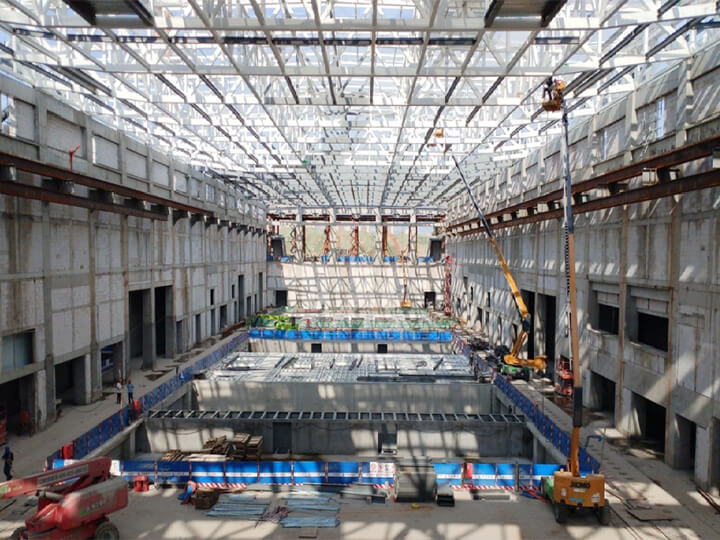

A steel structure factory represents a cutting-edge solution in modern industrial construction, renowned for its exceptional performance, structural integrity, and adaptability. Unlike traditional concrete or brick buildings, it leverages high-strength steel components—including columns, beams, trusses, and purlins—to form a robust, lightweight framework that redefines industrial space design.

1

Core Advantages

Steel boasts high tensile strength, rigidity, and fatigue resistance, enabling the factory to withstand extreme weather conditions (such as strong winds, earthquakes, and heavy snow) and heavy loads (e.g., overhead cranes, production equipment, and storage racks). The modular design ensures uniform force distribution, minimizing structural deformation and extending the building’s service life to 50+ years.

Prefabricated steel components are manufactured in factories with precision (tolerance within ±2mm) and then transported to the site for assembly. This off-site production reduces on-site construction time by 30-50% compared to traditional methods—typically a 10,000㎡ steel factory can be completed in 2-3 months. The bolted or welded connections simplify installation, lowering labor costs and minimizing construction waste.

Steel’s high strength-to-weight ratio allows for large-span structures (up to 100m without internal columns), creating unobstructed open spaces ideal for production lines, warehousing, and logistics. The modular system also supports easy expansion or renovation—additional bays can be added, or internal layouts adjusted, without compromising the original structure.

Steel is 100% recyclable, aligning with green building standards and reducing carbon footprint. The structure’s tight envelope, combined with insulated steel panels (EPS, PU, or rock wool), enhances thermal insulation and soundproofing, cutting energy consumption for heating and cooling by 20-30%. Moreover, prefabrication reduces on-site dust, noise, and waste, making construction more eco-friendly.

3

Quality & Safety Standards

All steel components comply with international standards such as AISC (American Institute of Steel Construction), EN 1090 (European), or GB 50017 (Chinese). The structure undergoes rigorous quality control—from material testing (tensile, impact, corrosion resistance) to non-destructive testing (NDT) of welds. Fire protection measures (intumescent paint, fireproof boards) and anti-corrosion treatments (galvanizing, painting) ensure long-term safety and durability.

4

Why Choose a Steel Structure Factory?

- It offers a perfect balance of cost-effectiveness, durability, and sustainability.

- Whether you need a small workshop or a large-scale industrial complex, a steel structure factory adapts to your needs, reduces operational costs, and supports future growth. It’s not just a building— it’s an investment in efficiency and resilience.