Description

Innovation, Efficiency and Sustainability

Steel structure commercial buildings refer to commercial premises (including office buildings, shopping malls, logistics centers, and mixed-use complexes) whose load-bearing systems primarily rely on high-strength steel components. Combining advanced structural design with prefabrication technology, this building type has become the mainstream choice for modern commercial construction, thanks to its outstanding performance in safety, efficiency, and sustainability. Unlike traditional concrete structures, steel-framed commercial buildings feature a “factory-made + on-site assembly” model that redefines the standards of commercial construction.

1

Core Structural Types

Steel structure commercial buildings adopt diversified structural solutions tailored to different commercial functions, ensuring optimal performance and space utilization:

This structure combines the high strength of steel frames with the rigidity of concrete core tubes, forming a balanced and efficient load-bearing system. All steel components (such as beams, columns, and connectors) are prefabricated in factories with precision, and then quickly assembled on-site using high-strength bolts—avoiding on-site welding pollution and reducing construction waste by 85% compared to traditional methods . For a 20-story commercial office building, the main structure can be completed in just 12 months, which is 50% shorter than the construction period of concrete structures . The flatness error of the wall surface is controlled within 3mm (about the thickness of a coin), fundamentally solving common problems such as water seepage and cracking in traditional buildings .

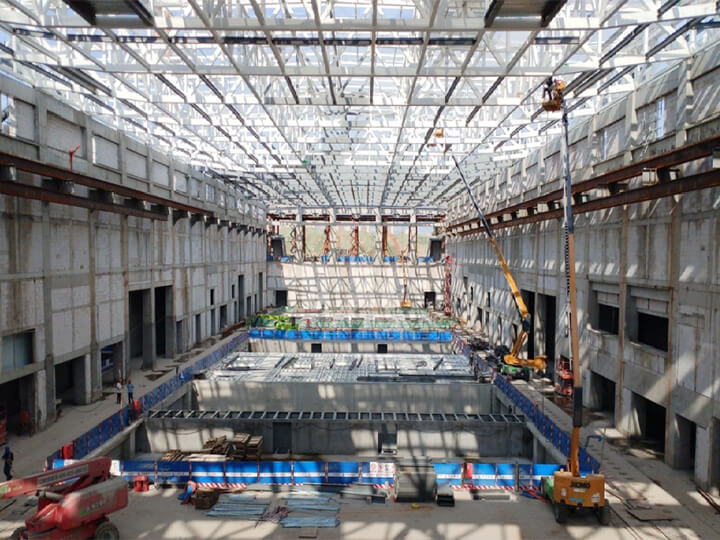

Ideal for open commercial spaces such as shopping mall atriums, large conference halls, and logistics warehouses, this structure uses H-steel trusses to achieve a maximum single span of 60 meters. Compared with traditional concrete beams, its space utilization rate is increased by 30%, allowing flexible division of functional areas (such as open shopping zones, private brand stores, or co-working spaces) to adapt to the dynamic business needs . The integrated intelligent ceiling system can adjust lighting and acoustics according to the scene, creating a comfortable commercial environment—for example, reducing the noise level in meeting areas to below 40dB .

2

Unparalleled Advantages

Steel structure commercial buildings stand out in the market due to their comprehensive performance advantages, bringing tangible value to investors, operators, and users:

- Super Safety and Durability

High-strength steel materials (such as Q355B/C steel) with a compressive strength of 345-420MPa provide a solid “skeleton” for the building . Equipped with shock-absorbing bearings and anti-seismic dampers, the structure can absorb 30% of seismic energy, achieving an 8-degree seismic fortification standard—much higher than the 7-degree standard of concrete structures . In terms of fire resistance, the development of fire-resistant steel has broken through the limitations of traditional fire-resistant coatings: new fire-resistant steel can maintain high strength at 600°C while ensuring good weldability and anti-seismic performance, reducing the need for thick fire-resistant coatings and saving interior space . For coastal commercial projects, the steel-concrete composite structure can resist level 12 typhoons (wind load of 3.0kN/㎡) with the support of steel plate shear walls inside the concrete core tube . - Cost Efficiency Throughout the Life Cycle

In terms of initial investment, the unit cost of the steel-concrete composite structure is about $800-1000 USD/㎡, which saves 20% of steel consumption and reduces the comprehensive cost by 15% compared with pure steel structures . The light weight of the steel structure (about 1/3 of the concrete structure) reduces the load on the foundation, lowering the foundation treatment cost by 40%—especially suitable for soft soil areas in coastal cities . In the long run, the service life of steel structure commercial buildings can reach 50-100 years, and the later maintenance cost accounts for less than 15% of the total life cycle cost (while that of concrete structures exceeds 35%) . The recyclability of steel further increases its residual value—structural steel has a recycling rate of 93% and can be 100% recycled without quality loss . - Green Sustainability and Low Carbon Emissions

Steel is the most sustainable construction material. 93% of the new steel members used in commercial buildings come from recycled materials (such as waste cars and decommissioned bridges), and the CO₂ emissions of electric arc furnace (EAF) steelmaking are 75% lower than those of traditional steelmaking . Matching with photovoltaic integrated roofs, a steel structure commercial building can generate electricity to meet 20% of its daily power demand, and the energy-saving rate of the external wall insulation system can reach 65% . These advantages make it easy to obtain international green building certifications such as LEED, helping investors enjoy green building subsidies and reduce operating electricity costs by 30% . - Strong Future Adaptability

Steel structures are highly modifiable, which is crucial for commercial buildings that need to adjust functions with business development. Steel beams and columns can be reinforced to bear additional loads (such as adding dense server rooms for financial companies) without affecting the overall floor plan; new floor openings can be easily added to install staircases or mechanical equipment, and even vertical expansion of floors is feasible . A typical case is the transformation of an abandoned power station in Lansing, Michigan, into a modern office space—realizing the reuse of the building with minimal structural modification . For commercial projects that may relocate in the future, 80% of the steel components can be disassembled and reused, reducing the cost of function replacement by 60% .

3

Future Development Trend

With the advancement of decarbonization in the construction industry, steel structure commercial buildings are moving towards a more intelligent and low-carbon future. On one hand, the integration of BIM (Building Information Modeling) technology realizes full-process digital management from component prefabrication to on-site assembly, further improving construction precision and efficiency. On the other hand, the combination of steel structures with renewable energy systems (such as large-scale photovoltaic roofs and rainwater recycling systems) is becoming more and more mature—for example, the Saxum Vineyard Equipment Barn in California uses its steel roof to generate 30% more electricity than it consumes . Major steel manufacturers have also made clear carbon reduction commitments: Nucor plans to reduce greenhouse gas intensity by 35% by 2030, and Steel Dynamics aims to achieve carbon neutrality by 2050 .

4

Conclusion

In conclusion, steel structure commercial buildings are not only a product of technological innovation but also a practice of sustainable development. They provide a more efficient, safe, and flexible solution for the commercial real estate market, and will continue to lead the development direction of modern commercial construction.