Description

A Revolutionary Spatial Structural System

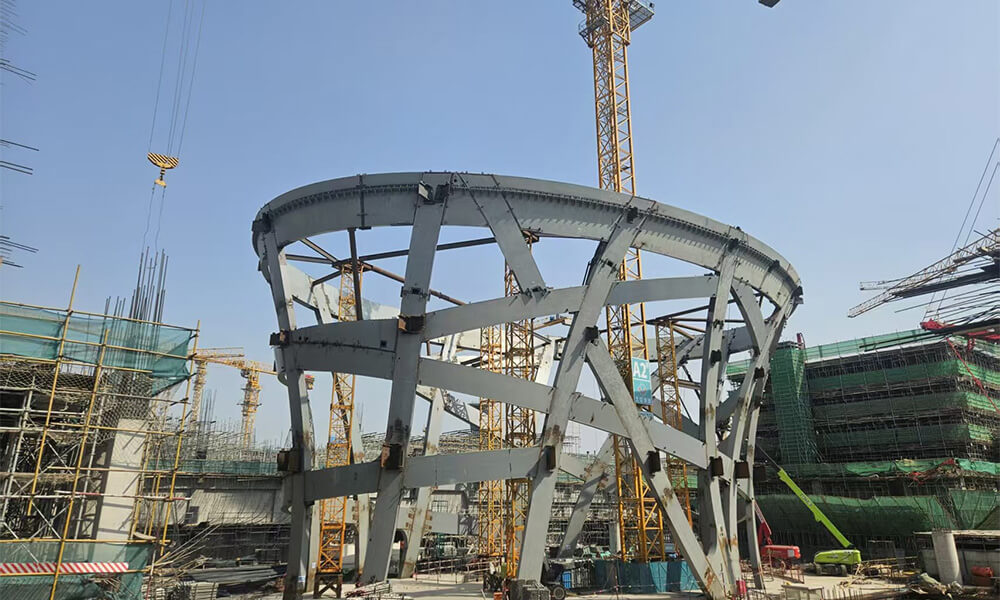

Steel Space Grid Structure, commonly referred to as steel space truss or spatial grid, is a sophisticated three-dimensional structural system composed of multiple steel members (such as tubes, angles, or channels) connected at nodes in a regular geometric pattern—typically triangular, quadrangular, or hexagonal. This unique spatial configuration transforms individual linear members into a unified, load-bearing network, enabling the structure to span large areas with exceptional stability. Unlike planar steel structures or traditional trusses, it distributes external loads (including dead weight, live load, wind load, and seismic load) evenly across all members in three dimensions, making it a preferred choice for large-span buildings and infrastructure projects.

1

Core Structural Features: Three-Dimensional Stability and Efficiency

The primary advantage of the steel space grid structure lies in its optimized force transmission mechanism. Each steel member in the grid primarily bears axial tension or compression, avoiding the bending and shear stresses that plague planar structures. This axial force transmission maximizes the material utilization efficiency of steel—typically reducing the overall steel consumption by 30%-50% compared to traditional beam-column structures for the same span. The geometric regularity of the grid (e.g., triangular units that resist deformation) further enhances the structure’s rigidity and stability, enabling it to withstand lateral forces like strong winds and earthquakes with minimal displacement.

Another defining feature is its lightweight nature combined with large-span capability. Steel space grid structures can easily cover spans ranging from 20 meters to over 100 meters without the need for intermediate supporting columns, which is crucial for creating unobstructed interior spaces. The use of high-strength steel tubes (such as Q355B or Q460) and precision-cast nodes further reduces the structure’s self-weight, lowering the load requirements for foundations and reducing overall construction costs. Additionally, the modular design of the grid allows for standardized production of members, ensuring consistent quality and simplifying on-site assembly.

2

Key Components: Members and Nodes

The steel space grid structure consists of two core components: structural members and connecting nodes, both of which are critical to its performance. Structural members are mainly hollow steel tubes (circular or square) due to their superior torsional stiffness and material efficiency—hollow tubes weigh less than solid bars while providing equivalent load-bearing capacity. For special applications (e.g., high-corrosion environments), stainless steel or galvanized steel members are used to enhance durability.

Nodes, the “joints” that connect multiple members, are the most technically demanding part of the structure. Common node types include bolted spherical nodes, welded hollow spherical nodes, and cast steel nodes. Bolted spherical nodes are widely used for their convenience in on-site assembly—steel tubes are connected to prefabricated spherical nodes via high-strength bolts, eliminating the need for on-site welding and accelerating construction. Welded hollow spherical nodes, formed by welding two hemispheres, offer higher load-bearing capacity and are suitable for heavy-duty projects. Cast steel nodes, customized for complex geometric configurations, ensure smooth force transmission in irregular grids.

3

Typical Application Scenarios: Spanning Beyond Boundaries

The versatility and large-span capability of steel space grid structures make them indispensable in a wide range of large-scale projects. In transportation infrastructure, they are extensively used as roof structures for airports, railway stations, and highway service areas—for example, the roof of Beijing Daxing International Airport utilizes a massive steel space grid to cover its 700,000-square-meter terminal, creating a column-free waiting area. In industrial facilities, they serve as roofs for large workshops, warehouses, and power plant coal yards, accommodating the installation of heavy equipment and ensuring unobstructed operational space.

In public buildings, steel space grid structures enable bold architectural designs, such as stadiums, exhibition halls, and concert halls. The National Stadium (Bird’s Nest) in Beijing uses a modified steel space grid structure (intertwined steel members) to form its iconic exterior, combining structural stability with artistic expression. They are also used in special projects like large-span bridges (as deck support structures), offshore platforms, and even temporary emergency shelters, thanks to their rapid assembly and disassembly capabilities.

4

Advantages in Construction: Efficiency, Durability, and Sustainability

Steel space grid structures offer significant advantages in construction efficiency. Most members and nodes are prefabricated in factories with high-precision machining (CNC cutting, automatic welding), ensuring that on-site work is limited to hoisting and assembly. This modular construction reduces on-site construction time by 40%-60% compared to traditional reinforced concrete structures, minimizing weather-related delays and labor costs. The lightweight nature of the structure also reduces the complexity of foundation construction—shallow foundations can often be used instead of deep piles, further shortening the project timeline.

In terms of durability and sustainability, steel space grid structures excel due to steel’s inherent properties. Steel is corrosion-resistant when treated with hot-dip galvanizing, epoxy coating, or other anti-corrosion measures, extending the structure’s service life to 50-100 years. Steel is also 100% recyclable, and the prefabricated nature of the structure reduces construction waste by over 70% compared to on-site cast concrete. Additionally, the open spatial configuration of the grid facilitates natural ventilation and lighting in buildings, reducing energy consumption for HVAC and lighting systems.

5

Technological Development and Future Trends

With the advancement of building information modeling (BIM) technology, parametric design, and digital fabrication, steel space grid structures are entering a new era of precision and innovation. BIM software enables 3D modeling of the entire grid, optimizing member sizes and node configurations to minimize material usage while ensuring structural safety. Digital fabrication technologies like 3D printing of complex nodes and robotic welding further improve production accuracy and efficiency. Future trends also include the integration of new materials (e.g., fiber-reinforced polymer composites) with steel, enhancing corrosion resistance and reducing weight, as well as the development of intelligent monitoring systems (using sensors embedded in members) to real-time track structural health. As the demand for large-span, sustainable, and architecturally innovative buildings grows, steel space grid structures will remain at the forefront of modern structural engineering.