Description

Polyurethane sandwich panel (often abbreviated as PIR/PUR sandwich panel) is a high-performance composite building material. It consists of two outer layers (usually color-coated steel sheets, aluminum alloy sheets, or fiber cement boards) and a core layer of rigid polyurethane foam bonded under high temperature and pressure.

1

Core Features

The closed-cell structure of polyurethane foam gives it low thermal conductivity (typically 0.022-0.026 W/(m·K)), outperforming traditional insulation materials like rock wool or EPS.

The combination of outer panels and core layer provides high compressive, bending, and shear strength, suitable for load-bearing applications.

Compared to concrete or brick walls, it is much lighter, reducing building load and shortening construction time with modular installation.

High-quality panels feature waterproof outer layers and flame-retardant core materials (meeting B1/B2 fire ratings), ensuring long-term durability.

Effectively blocks air-borne and structure-borne noise, while its thermal insulation property lowers heating and cooling energy consumption.

2

Typical Applications

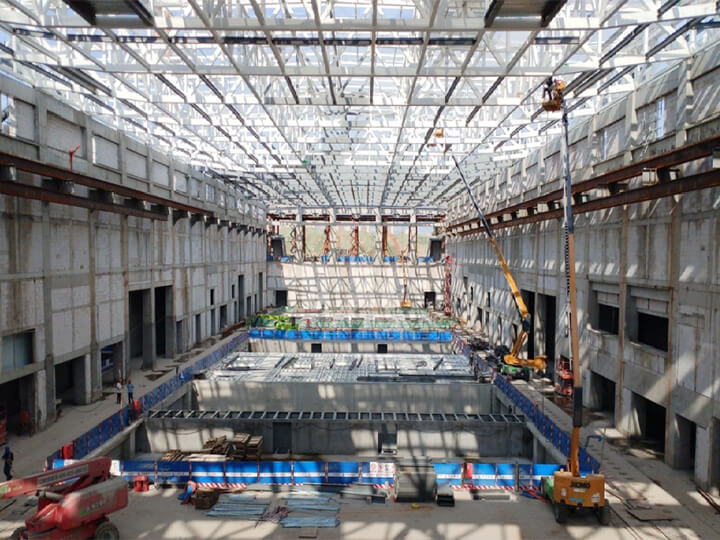

- Industrial buildings: Factory workshops, warehouses, and steel structure plants (for walls and roofs).

- Commercial buildings: Shopping malls, cold storage facilities, and logistics centers (especially cold storage due to excellent thermal insulation).

- Civil buildings: Prefabricated houses, modular buildings, and exterior insulation systems for residential buildings.

- Special projects: Clean rooms, data centers, and mobile cabins (requiring strict temperature and humidity control).

3

Advantages in Construction

- Shortens construction period by 30-50% compared to traditional materials, improving project efficiency.

- Reduces overall building weight by 20-40%, lowering foundation costs and structural design complexity.

- Offers long service life (15-25 years) with minimal maintenance, thanks to corrosion-resistant outer layers and stable core material performance.

- Customizable: Available in various thicknesses (50-200mm), colors, and sizes to meet different design and functional needs.