Description

Colored steel plate (also known as pre-painted steel plate) is a high-performance building material made by coating a steel substrate with organic coatings through processes like cleaning, chemical treatment, priming, and topcoating. It combines the strength of steel with the corrosion resistance and aesthetics of coatings, becoming a staple in modern construction and manufacturing.

1

Core Advantages

The organic coating forms a protective barrier against rust, moisture, and UV radiation, with a service life of 10–20 years (extendable with proper maintenance).

Available in a wide range of solid colors (e.g., red, blue, gray) and finishes (matte, glossy, textured), adapting to diverse design needs.

Lighter than traditional building materials like concrete or brick, reducing structural load and simplifying on-site construction.

Low production and maintenance costs, coupled with high reuse rates, offering long-term economic benefits.

2

Typical Applications

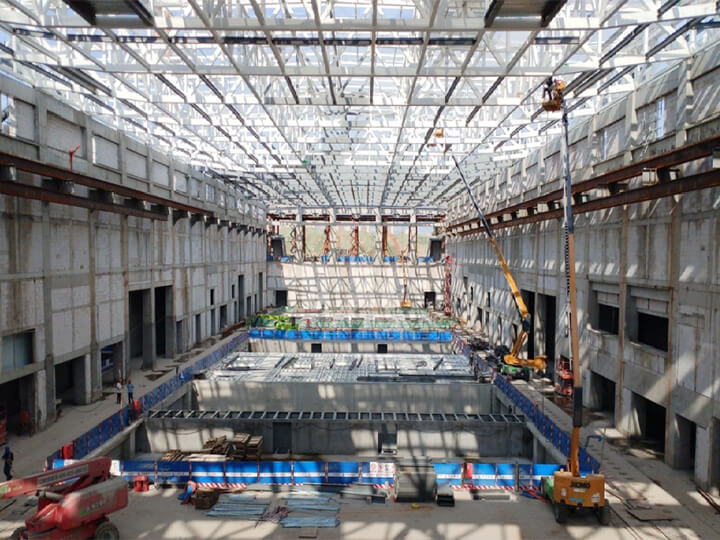

- Building Envelopes: Roofs, walls, and facades of industrial workshops, warehouses, commercial buildings, and residential prefabricated houses.

- Interior Decoration: Partition walls, ceiling panels, and decorative cladding in shopping malls, offices, and public spaces.

- Transportation & Manufacturing: Body parts of vehicles (trailers, vans), containers, electrical cabinets, and home appliance casings (refrigerators, washing machines).

- Agricultural Facilities: Greenhouse frames and sheds, leveraging its corrosion resistance to withstand outdoor agricultural environments.

3

Key Advantages Over Traditional Materials

- Outperforms uncoated steel in corrosion resistance, eliminating frequent anti-rust maintenance.

- More flexible than concrete, allowing for curved or customized shapes in architectural design.

- Faster to install than brick or stone, shortening construction cycles significantly.

- Environmentally friendly, as the steel substrate is recyclable and the coating materials meet low-VOC standards.