Packaging & Shipping

The core of packaging for steel structure components lies in “damage prevention, moisture protection, and facilitation of transportation and unloading“. Customized solutions must be designed based on component type, transportation distance, and environmental conditions to avoid deformation, corrosion, or damage during transit.

Core Packaging Principles

Prevent paint damage and edge deformation caused by collision or friction between components, with special protection for key parts such as welds and bolt holes.

Avoid corrosion during sea shipping or in humid environments, meeting the requirements of long-distance international transportation.

Packaging specifications should match transportation vehicles (containers, flatbed trucks) to facilitate hoisting, inventory checking, and on-site unloading.

Clearly mark component information to enable easy verification and installation sequencing at the destination.

Packaging Methods for Different Components

Heavy-Duty Components (Steel Columns, Steel Beams, Crane Beams)

Adopt bare packaging + reinforcement method. Place wooden blocks under components (spacing ≤ 2 meters) to avoid direct contact with the ground or carriage.

When stacking components of the same specification, insert rubber pads or wooden boards between layers. Secure with steel wire ropes and buckles to prevent sliding and collision during transportation.

Weld corner protectors at both ends of components or cover with steel tube sleeves to protect end parts and bolt holes. Apply protective film to weld areas.

Light-Duty Components (Purlins, Tie Bars, Braces)

Bundle and package by length. Control the weight of each bundle between 1-2 tons (for easy hoisting) and fasten with steel straps or high-strength packing belts (bundling spacing ≤ 1.5 meters).

Wrap the surface of components with waterproof film before bundling. For coastal or sea shipping, add an extra layer of rain cloth and place desiccants inside for moisture protection.

For thin-walled or deformable components (e.g., C-shaped steel purlins), insert steel tubes or wooden blocks internally for support to prevent extrusion deformation.

Small Parts and Accessories (Bolts, Washers, Gusset Plates)

Classify standard parts such as bolts and nuts by specification, and pack them into waterproof cartons or iron buckets. Fill the buckets with foam or bubble film for shockproofing.

Group small parts such as gusset plates and connecting plates by installation position, bundle with iron wire or packing belts. Apply anti-rust oil to the surface and wrap with waterproof film.

Mark all small parts packages with “Accessories”, “Moisture-Proof”, and “Fragile” labels. Avoid mixed loading with heavy-duty components to prevent extrusion.

Special Components (Truss Members, Special-Shaped Nodes)

Classify standard parts such as bolts and nuts by specification, and pack them into waterproof cartons or iron buckets. Fill the buckets Number truss members according to assembly sequence. Use dedicated brackets to fix them when stacking in layers to avoid member bending or node deformation.

Wrap special-shaped nodes with customized foam or wooden molds. Wind the outer layer with waterproof film and woven cloth to ensure stable posture during transportation.

Auxiliary Packaging Requirements

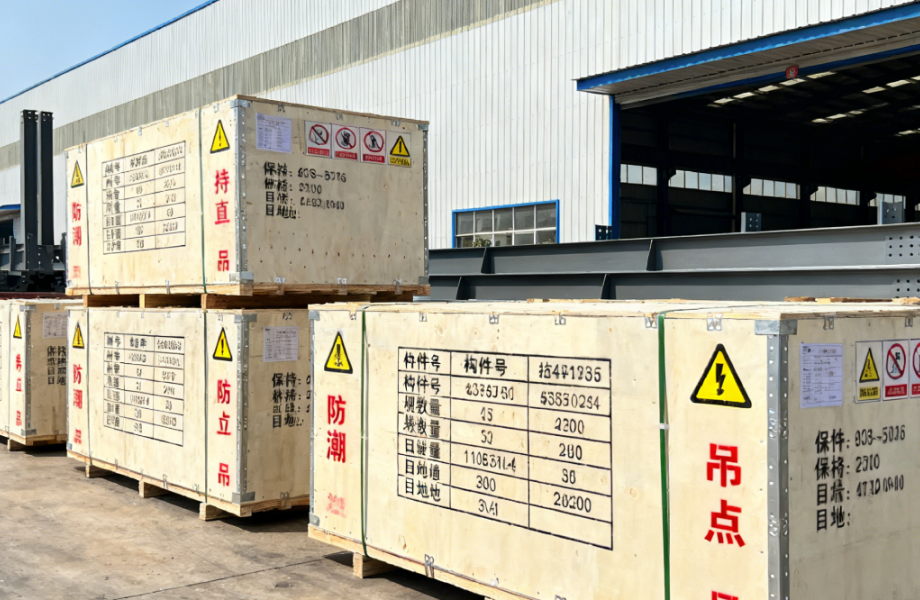

Marking Specifications

Each packaging unit should be labeled with component number, specification, quantity, weight, destination, and warning signs such as “Keep Upright”, “Moisture-Proof”, and “Lifting Points”. Adapt to international multi-language needs (both Chinese and English can be marked).

Moisture-Proof Reinforcement

For sea shipping or transportation during rainy seasons, fully cover with rain cloth. Elevate the bottom to keep it away from the carriage floor (to prevent condensation) and apply an additional coat of temporary anti-rust paint or spray anti-rust agent on the component surface.

Transport Adaptation

For container transportation, the component length should not exceed the internal diameter of the container. For over-length components, use open-top trucks and install anti-collision warning signs at both ends. For bare-packaged components, lay rubber plates in the carriage to reduce friction damage.