Case Overview

Tiankai Southeast Green Building Technology (Henan) Co., Ltd. participated in the Shaanxi Metaverse Complex Project – the Daqin Metaverse Intelligent Complex (“Generation O” Youth Power Center) in Xianyang High-tech Zone – as a steel structure professional subcontractor, providing integrated services for detailed design, component fabrication, and on-site installation of spatial special-shaped steel structure systems. The project focused on realizing the circular form and futuristic styling rooted in the “0 and 1” concept. Through the full-chain innovation of digital design – special-shaped structure – intelligent construction – collaborative management, the system overcame challenges in precision and stability for large-span spatial special-shaped steel structures, delivering an efficient and accurate steel structure solution for the metaverse complex’s futuristic appearance, and highlighting the technical and aesthetic advantages of prefabricated steel structures in public buildings.

Core Work Scope

- Supported on-site construction by completing detailed construction drawing design for the steel structure of the circular main body and large-span dome, focusing on solving complex structural challenges such as circular frames, special-shaped pipe trusses, and joint connections.

- Used BIM simulation for key processes including overall dome lifting and segmented hoisting, predicted structural deformation, optimized lifting points and sequences, and ensured installation accuracy and safety.

- Completed steel structure modeling for the circular main body and funnel-shaped dome via BIM + parametric design, achieving precise correlation between component dimensions and curved forms with error controlled within 3mm, guaranteeing smooth exterior appearance.

- Built a 1:1 digital twin model integrating data from steel structure, MEP, curtain wall and other disciplines, resolving pipeline-steel component clashes in advance, reducing on-site rework, and improving construction efficiency.

Two Major Innovations of the Project

1. Spatial Special-Shaped Steel Structure System (Structural System Innovation)

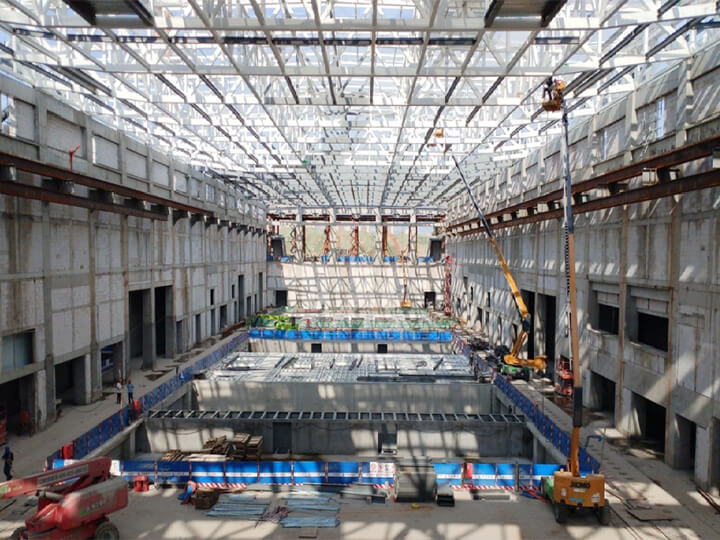

- Funnel-shaped single-layer lattice shell dome: Adopting a single-layer grid spatial dome, it is assembled and welded from 1,200 cross beams and 463 precision nodes, with a maximum unsupported span of 45m, a vertical height of 16m, and a total weight of approximately 400 tons. Rigidly connected to the main steel structure, it balances styling and mechanical performance.

- Integrated circular frame and special-shaped joints: Customized circular box columns and special-shaped pipe trusses, processed via intersecting line cutting and factory pre-assembly, solve challenges in force transmission and joint connection for the circular form, adapting to the building’s curved geometry and load requirements.

- Prefabricated component adaptation: Standardized production of H-shaped beams/columns, steel truss floor slabs and other components, coordinated with special-shaped components to achieve a combination of customization + standardization, improving assembly efficiency.

2. Construction Method and Equipment Innovation (On-Site Construction Innovation)

- Ground assembly + hydraulic synchronous integral lifting: Targeting the dome’s large span and heavy tonnage, the project adopted 8 lifting towers + computer-controlled hydraulic synchronous lifting technology to hoist the 400-ton dome into place in one piece – the first case of large-tonnage high-altitude lattice shell integral lifting in Shaanxi Province. This reduced high-altitude operation risks and completed the milestone within 1 month.

- Non-destructive testing and intelligent welding: Implemented 100% non-destructive testing (NDT) on critical parts such as box columns and truss joints. Adopted robotic welding and intersecting line cutting technology to ensure weld quality and component precision.

- Segmented hoisting and high-altitude assembly: Special-shaped components were prefabricated in segments at the factory and assembled on-site at height. With a dedicated hoisting plan, the overall form accuracy of the circular main body and dome was ensured.