Covers multiple scenarios

The application of steel structures in the PV industry covers multiple scenarios, each tailored to specific environmental and functional requirements.

Ground-mounted PV power plants, the most common type, widely adopt light steel portal frames and space grid structures as supports. These structures can be flexibly deployed in deserts, grasslands, and wastelands, with adjustable angles to maximize solar energy absorption. For areas with complex terrain, the modular design of steel components allows for quick adaptation to slopes and undulations, minimizing earthwork and protecting the original ecosystem.

BIPV projects

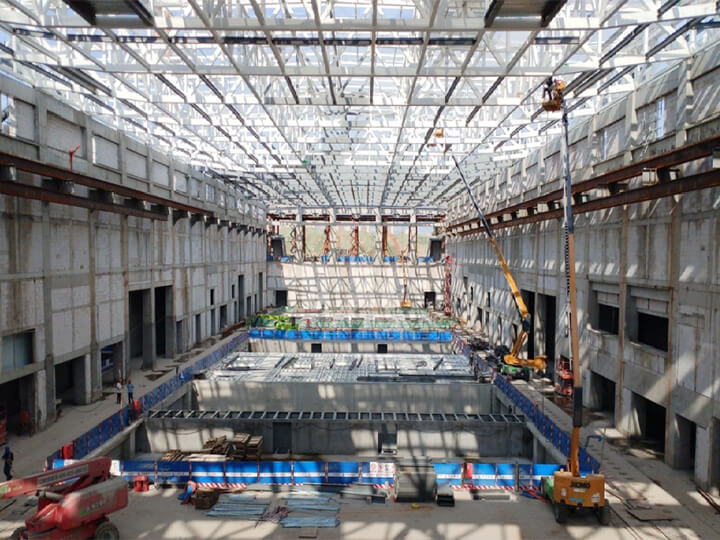

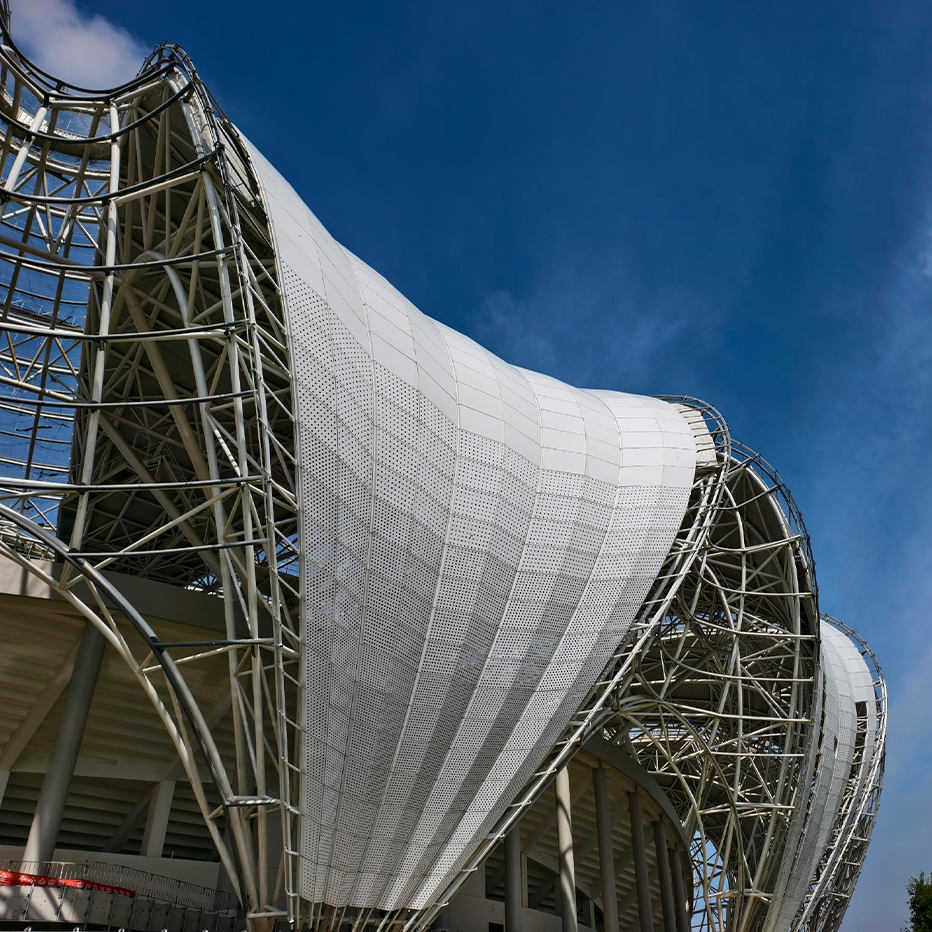

BIPV projects represent a revolutionary integration of PV technology and architecture, where steel structures serve as both building envelopes and PV module carriers. Large industrial facilities, such as steel mills and water treatment plants, often use steel space grid or portal frame structures to construct large-span roofs for PV installation. A typical example is the BIPV project at Longteng Special Steel, which employs a three-span double-layer cylindrical latticed shell steel structure to support PV modules over its port storage yard, with a maximum span of 223.7 meters . Similarly, the Linjiang Water Treatment Plant’s PV project uses steel grid structures with a maximum continuous span of 196 meters over its secondary sedimentation tanks, demonstrating steel’s ability to cover large functional areas. Additionally, steel structures are widely used in rooftop PV systems for commercial and residential buildings, where light steel brackets with high strength-to-weight ratios avoid overloading the original building.

Core Advantages: Why Steel Structures Dominate PV Applications

- The dominance of steel structures in the PV industry stems from their unique combination of mechanical properties and construction advantages. Firstly, exceptional load-bearing and stability ensure the safety of PV modules. Steel components can easily bear the weight of PV panels, as well as external loads such as strong winds, heavy snow, and hail. The Longteng Special Steel project, for instance, is designed to withstand typhoons above level 12 and earthquakes above magnitude 7, ensuring uninterrupted PV operation in extreme weather . The triangular or quadrangular geometric configuration of steel space grids further distributes loads evenly, reducing local stress concentration.

- Secondly, large-span capability and design flexibility optimize land and space utilization. Steel structures can cover spans from tens to hundreds of meters without intermediate supports, making them ideal for covering industrial yards, water bodies, and transportation hubs—turning underutilized spaces into clean energy generation sites. The modular production of steel components (such as prefabricated bolted spherical nodes) enables on-site assembly with minimal welding, shortening construction cycles by 30%-50% compared to traditional structures. The Longteng Special Steel project, involving 16,000 tons of steel and nearly one million steel tubes, was completed in just 15 months , highlighting this efficiency.

- Thirdly, durability and corrosion resistance meet the long-term operational needs of PV projects. PV systems typically have a service life of 25-30 years, and steel structures treated with hot-dip galvanizing or epoxy coating can maintain structural integrity for over 50 years, matching or exceeding the lifespan of PV modules. In high-humidity environments like water treatment plants or coastal areas, galvanized steel or stainless steel components effectively resist corrosion, reducing maintenance costs. Moreover, steel is 100% recyclable, aligning with the low-carbon nature of the PV industry and enhancing the overall sustainability of projects.

Typical Project Cases: Showcasing Practical Value

The Longteng Special Steel BIPV project stands as a landmark in the integration of steel structures and PV technology. This project uses a steel latticed shell structure to cover a 176,000-square-meter port area, supporting 68,000 monocrystalline PV panels . Beyond generating 48.5 million kWh of electricity annually—saving 38,000 tons of standard coal and reducing 25,000 tons of carbon dioxide emissions—the steel structure also fully encloses the ore yard, lowering PM2.5 levels to 7 mg/m³ and eliminating dust pollution . This “PV + Steel” model has become a benchmark for industrial low-carbon transformation.

Another notable case is the 30MWp distributed PV project at Xiaoshan Linjiang Water Treatment Plant, the largest of its kind in China. The project employs a hybrid steel structure system: portal steel frames with a maximum span of 93.4 meters over aeration tanks and steel grid structures with a maximum span of 196 meters over secondary sedimentation tanks . It generates approximately 30 million kWh of clean electricity yearly, meeting the plant’s internal power needs and feeding surplus power into the grid—reducing 8,500 tons of standard coal consumption and 25,000 tons of carbon dioxide emissions annually . These cases demonstrate how steel structures enable PV projects to achieve both energy production and environmental protection goals.

Future Development Trends: Innovation Driving Further Integration

The future of steel structures in the PV industry will be shaped by technological innovation and diversified demand. With the popularization of BIM (Building Information Modeling) technology, steel structure design for PV projects will become more precise—enabling parametric optimization of component sizes and node configurations to minimize material usage while ensuring structural safety. The development of high-strength, lightweight steel materials (such as Q690 high-strength steel) will further reduce the self-weight of structures, expanding their application in high-rise building rooftops and complex terrains.

Intelligent integration is another key trend. Embedding sensors in steel components will enable real-time monitoring of structural health—tracking stress, deformation, and corrosion to ensure the safe operation of both the steel structure and PV system. Additionally, the combination of steel structures with energy storage systems and smart grids will create a more stable and efficient renewable energy ecosystem. As the PV industry expands into offshore, floating, and other new areas, steel structures will continue to evolve, providing reliable support for the global energy transition.

Conclusion

The integration of steel structures and the PV industry represents a perfect synergy of engineering strength and sustainable development. Steel structures provide the PV industry with safe, efficient, and flexible supporting solutions, while the PV industry drives the innovation and application of steel structures in green energy fields. From large industrial BIPV projects to small rooftop installations, this partnership is playing a crucial role in reducing carbon emissions and promoting energy structure transformation. As technology advances, steel structures will undoubtedly remain a core supporting force for the PV industry, contributing more to the achievement of global carbon neutrality goals.