High-Performance Spatial Load-Bearing System

Our Steel Space Grid Structure is a premium three-dimensional load-bearing product engineered for large-span construction needs, designed to deliver exceptional stability, material efficiency, and architectural flexibility.

Composed of high-strength steel members (precision-welded or bolted tubes, angles, or I-sections) and durable connecting nodes, this structure forms a regular geometric network—typically triangular, quadrangular, or hexagonal—to distribute loads uniformly across the entire spatial framework. It is the ideal solution for projects requiring unobstructed interiors, long service life, and rapid on-site assembly, spanning industrial, commercial, and infrastructure sectors.

Product Core Composition & Craftsmanship

The structure integrates two key components, each manufactured to rigorous industry standards:

- Structural Members: Crafted from Q355B, Q460, or 304/316 stainless steel (customizable by requirement), the members are processed via CNC cutting, automatic welding, and hot-dip galvanizing. Hollow steel tubes are the primary choice for their superior strength-to-weight ratio, reducing overall structure weight by 30%-40% compared to solid steel components while maintaining equivalent load capacity.

- Connecting Nodes: Available in bolted spherical, welded hollow spherical, and cast steel configurations. Bolted nodes enable tool-free on-site assembly for fast installation; welded nodes offer enhanced load-bearing for heavy-duty applications; cast steel nodes are tailored for complex geometric layouts, ensuring smooth force transmission between members.

All components undergo strict quality control—including ultrasonic flaw detection for welds, galvanization thickness testing, and dimensional accuracy checks—to meet ISO 9001 and AISC 360 standards.

Key Performance Advantages

- Superior Load-Bearing & Stability: The spatial grid design converts external loads (dead weight, live load, wind, seismic force) into axial tension/compression on members, eliminating excessive bending stress. It withstands wind speeds up to 60 m/s and seismic intensity up to magnitude 8, with minimal deformation even under extreme conditions.

- Large-Span Capability: Covers spans from 20m to 150m without intermediate supports, maximizing usable space. Ideal for stadiums, exhibition halls, and industrial workshops where unobstructed areas are critical.

- Lightweight & Cost-Efficient: High strength-to-weight ratio reduces foundation load requirements by 25%-35%, lowering overall project costs. Steel consumption is 30%-50% less than traditional beam-column structures for the same span.

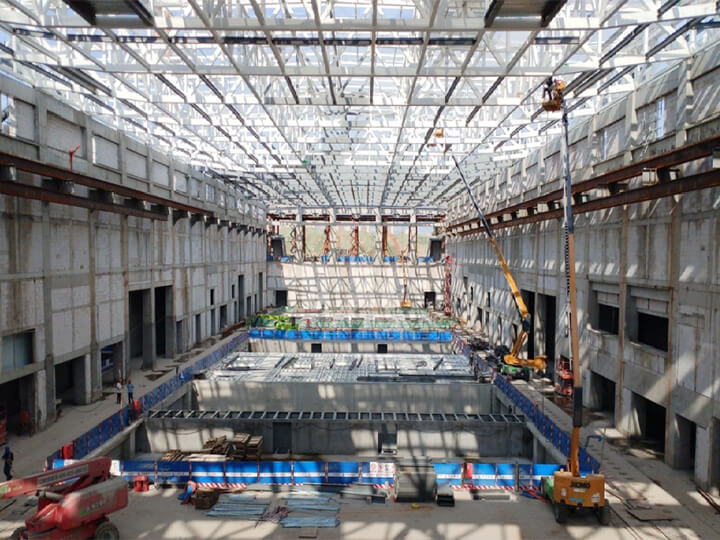

- Rapid Installation: 80% of components are prefabricated in the factory. On-site work focuses on hoisting and assembly, cutting construction time by 40%-60% compared to reinforced concrete structures. A 10,000㎡ grid can be installed in 4-6 weeks.

- Durable & Low-Maintenance: Hot-dip galvanization (zinc layer thickness ≥85μm) or epoxy coating provides corrosion resistance, ensuring a service life of 50-100 years. The open grid design prevents debris accumulation, requiring only annual visual inspections and occasional bolt tightening.

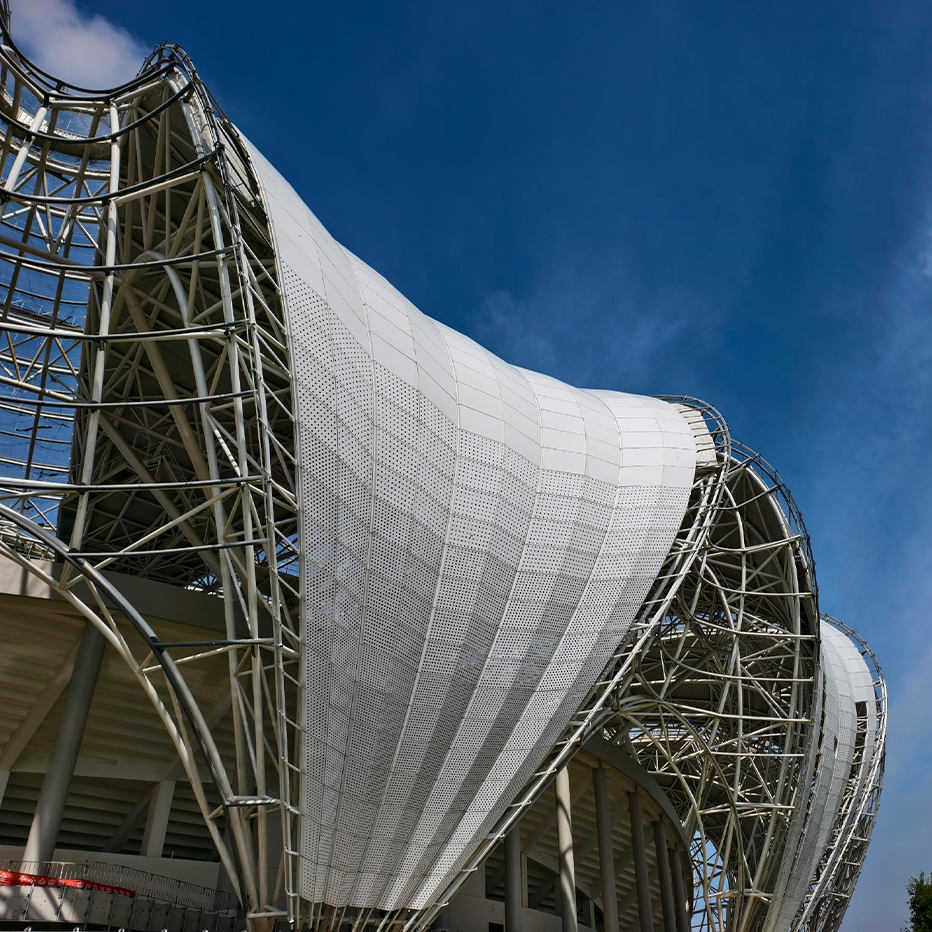

- Architectural Flexibility: Adaptable to curved, sloped, or irregular roof shapes. Compatible with glass, metal panels, and other cladding materials, supporting creative architectural designs.

- Typical Application Scenarios: Public Buildings: Stadiums, exhibition centers, concert halls, airport terminals (e.g., roof structures for large waiting areas).Public Buildings: Stadiums, exhibition centers, concert halls, airport terminals (e.g., roof structures for large waiting areas). Industrial Facilities: Factory workshops, power plant coal yards, warehouse roofs (supports heavy equipment and large-scale operations). Infrastructure: Highway service area roofs, railway station canopies, bridge deck supports. Special Projects: Large-span canopies, offshore platforms, temporary emergency shelters (rapid assembly/disassembly).

Why Choose Our Steel Space Grid Structure?

We combine advanced BIM parametric design with precision manufacturing to deliver tailored solutions for every project. Our team provides full-cycle support—from initial design and material selection to on-site installation guidance and after-sales maintenance. With a track record of supplying grids for landmark projects (including stadiums and industrial parks), we guarantee products that balance structural safety, cost efficiency, and architectural aesthetics. Whether for standard or custom requirements, our Steel Space Grid Structure is the reliable choice for large-span construction.