Steel Structures in Sports Venues: Engineering for Grandeur, Performance and Spectatorship

Sports venues—encompassing stadiums, arenas, gymnasiums, and aquatic centers—demand architectural solutions that balance unobstructed sightlines, massive span capabilities, and structural resilience to accommodate tens of thousands of spectators, heavy athletic equipment, and extreme weather conditions.

Steel structures have emerged as the definitive choice for such projects, leveraging their exceptional strength-to-weight ratio, design flexibility, and rapid construction potential to create iconic, functional venues worldwide. From the sweeping roofs of Olympic stadiums to the rigid frameworks of indoor arenas, steel forms the structural backbone that brings sports architecture to life, merging engineering excellence with the excitement of live competition.

Core Application Forms in Sports Venues

Steel structures adapt to the diverse functional requirements of different sports venues, with configurations tailored to span needs, spectator capacity, and sport-specific demands. Their versatility ensures optimal performance whether for outdoor football stadiums or indoor basketball arenas.

1. Stadium Roof Structures: Covering the Crowd

Outdoor stadiums (for football, rugby, or athletics) rely on steel to create expansive roof canopies that protect spectators while minimizing obstruction to field views and natural light. Key steel systems include:

- Steel Space Grid/Latticed Shells: The most widely used system for large stadiums, these three-dimensional networks of steel tubes form lightweight, rigid structures capable of spans up to 200 meters. The National Stadium (Bird’s Nest) in Beijing uses a modified steel space grid—composed of 42,000 tons of steel—to form its iconic interwoven roof, covering a 258,000-square-meter area while supporting 80,000 spectators.

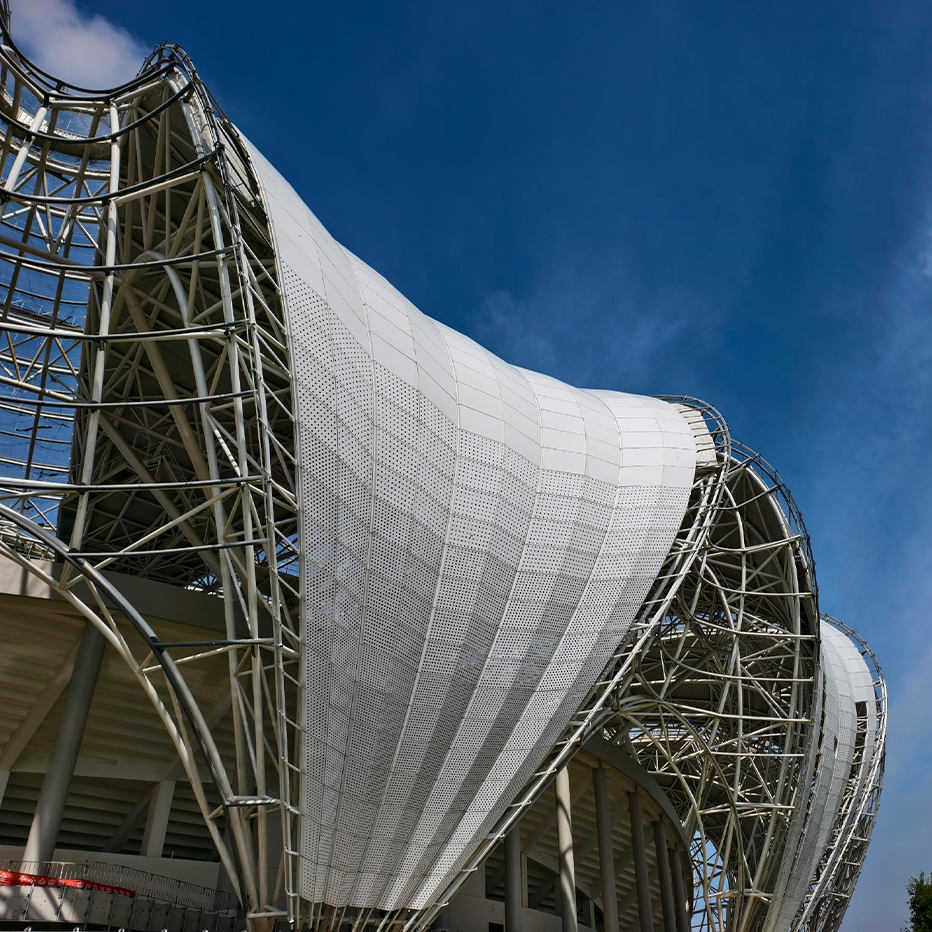

- Cable-Stayed Steel Roofs: For stadiums with asymmetrical designs, cable-stayed systems use steel towers and high-tensile steel cables to suspend roof panels. This minimizes the need for heavy support columns, ensuring unobstructed views from all seats. The Tokyo Olympic Stadium employs this system, with steel cables radiating from central towers to support its lightweight roof.

- Retractable Steel Roofs: A hallmark of modern premium stadiums, retractable roofs use steel trusses and rails to enable quick opening/closing (30–60 minutes) in response to weather. The Mercedes-Benz Stadium in Atlanta features a retractable steel roof with eight “petal” sections, each composed of steel frames and ETFE panels, allowing the venue to host events in all conditions.

2. Indoor Arena Structures: Rigidity for Intimate Competition

Indoor arenas (for basketball, volleyball, or ice hockey) require steel systems that balance span capability with acoustic performance and column-free interiors. Common configurations include:

- Steel Truss Systems: Parallel steel trusses—spaced 4–8 meters apart—form the roof structure, achieving spans of 40–100 meters. These trusses support suspended scoreboards, lighting rigs, and sound systems while maintaining a clear ceiling height of 10–15 meters (critical for indoor sports like volleyball). The Staples Center (now Crypto.com Arena) in Los Angeles uses steel trusses to cover its 20,000-seat arena.

- Steel Portal Frames with Purlins: For smaller indoor gymnasiums (1,000–5,000 seats), steel portal frames provide a cost-effective solution, with spans of 20–40 meters. Steel purlins connect the frames, supporting roof cladding and insulation to maintain comfortable indoor temperatures for athletes and spectators.

- Composite Steel Floors: Indoor arenas often use composite steel-concrete floors, where steel beams are topped with concrete slabs. This system supports heavy loads (e.g., ice hockey rinks, basketball courts) and reduces vibration, enhancing both athletic performance and spectator comfort.

3. Specialized Sports Venue Components

Steel structures also play a critical role in sport-specific venue elements, addressing unique functional demands:

- Aquatic Centers: Steel framing supports the large roof spans required for swimming pools, while corrosion-resistant steel (stainless steel, galvanized steel) withstands the high-humidity environment. The London Aquatics Centre for the 2012 Olympics uses a steel space frame roof spanning 160 meters, covering three Olympic-sized pools.

- Stadium Seating Structures: Steel bleachers and grandstands use lightweight steel framing to support thousands of seats while minimizing foundation loads. Cantilevered steel sections extend over walkways, maximizing spectator capacity without blocking circulation.

- Scoreboards and Lighting Towers: Steel poles and frames support massive LED scoreboards (up to 100 tons) and high-intensity lighting systems, ensuring visibility for both on-site spectators and broadcast audiences. These structures are engineered to withstand wind loads and vibration from crowd noise.

Key Advantages of Steel Structures for Sports Venues

Steel’s dominance in sports venue construction stems from its ability to address the unique challenges of these projects—massive spans, tight construction schedules, and the need for iconic design—while ensuring safety and functionality.

- Logistical Support Systems: Overhead cranes (single-girder, double-girder, or gantry cranes) for vertical and horizontal movement of heavy components; conveyor belts and automated guided vehicles (AGVs) for seamless material transfer between production stations; and loading docks with hydraulic levelers for efficient truck loading/unloading.

- Electronics Production: Cleanroom environments with controlled temperature (20-24℃) and humidity (45%-60%), HEPA filtration systems to remove particulate matter, and anti-static flooring to protect sensitive components. The structure is designed to minimize vibration, ensuring precision in microelectronics assembly.

- Heavy Machinery Manufacturing: Incorporates extra-strong foundations and overhead cranes with high lifting capacities (200-500 tons). The workshop is equipped with large roll-up doors for the entry/exit of oversized machinery and reinforced flooring for welding and forging operations.

- Food Processing: Features stainless steel wall panels and floors for easy cleaning, waterproofing systems to prevent moisture buildup, and temperature-controlled zones (refrigeration or freezing) for food storage and processing. The structure is designed to comply with food safety standards (e.g., FDA, HACCP).

Sustainability & Energy Efficiency

Modern industrial workshops increasingly prioritize sustainability to reduce environmental impact and operational costs. Key green features include:

- Ultra-Large Span Capability: Unobstructed Sightlines

The primary requirement for sports venues is unobstructed views from every seat, which demands spans far beyond the capabilities of concrete. Steel space grids and cable-stayed systems routinely achieve spans of 100–200 meters without intermediate columns, ensuring that even spectators in the upper tiers have clear views of the playing field. This span capability also eliminates barriers for large-scale events like concerts or festivals hosted in sports venues.

- High Strength-to-Weight Ratio: Reducing Foundation Costs

Steel’s exceptional strength relative to its weight (up to 250x that of concrete) reduces the overall load on venue foundations—a critical advantage for large stadiums with capacities of 50,000+ spectators. For example, the steel roof of the Rio de Janeiro Olympic Stadium weighs 70% less than an equivalent concrete roof, minimizing the need for deep, expensive foundations and reducing construction complexity, especially in areas with poor soil conditions.

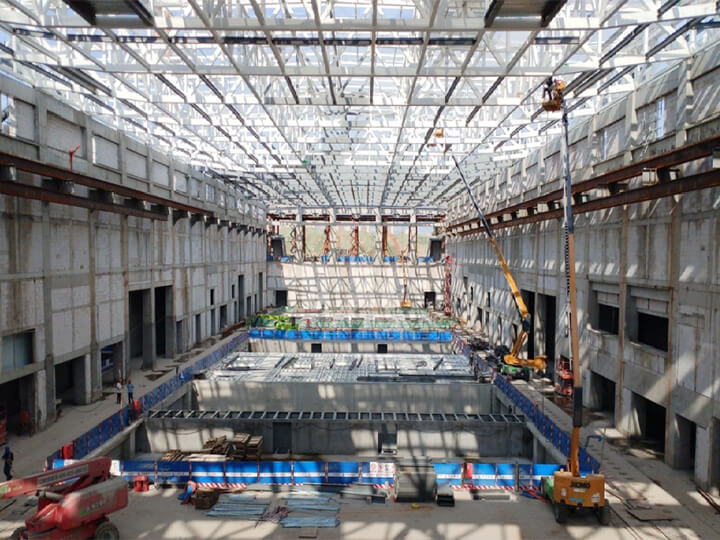

- Rapid Construction: Meeting Event Deadlines

Sports venues are often tied to fixed event deadlines (e.g., Olympics, World Cups), requiring fast, reliable construction. Steel components are prefabricated in factories with precision (CNC cutting, automated welding) and assembled on-site using bolted connections, reducing construction time by 30–50% compared to concrete. The Beijing National Stadium was constructed in just 3 years—half the time required for a similar concrete structure—enabling it to be ready for the 2008 Olympics.

- Design Flexibility: Creating Iconic Landmarks

Sports venues often serve as cultural landmarks, and steel’s malleability enables architects to create bold, memorable designs. Steel can be shaped into curved, angular, or organic forms—from the Bird’s Nest’s interwoven steel lattice to the sleek, aerodynamic roof of the Dubai International Stadium. This flexibility also allows for customization to reflect local culture, making sports venues symbols of their host cities.

- Durability and Resilience: Withstanding Extreme Conditions

Sports venues must withstand heavy use (tens of thousands of spectators, frequent event setups/teardowns) and extreme weather (hurricanes, snow, heat). Steel treated with hot-dip galvanizing (zinc layer thickness ≥85μm) or epoxy coating resists corrosion, while its ductility absorbs seismic energy and wind loads. The Mercedes-Benz Stadium’s steel roof is designed to withstand hurricane-force winds (130 mph), ensuring operational safety in all conditions.

Critical Engineering Considerations for Sports Venue Steel Structures

To maximize steel’s performance in sports venues, engineers address specialized challenges related to spectator safety, athletic performance, and event versatility:

- Wind and Seismic Resistance

Outdoor stadiums in windy or seismic regions require steel structures with enhanced lateral stiffness. Steel bracing systems, tuned mass dampers, and aerodynamic roof designs (e.g., curved edges to reduce wind uplift) are used to meet standards like ASCE 7 (wind) and AISC 341 (seismic). The Tokyo Olympic Stadium’s steel roof incorporates wind deflectors to minimize turbulence and noise for spectators.

- Vibration Control

Crowd noise, cheering, and stamping can cause floor and roof vibrations, which reduce spectator comfort and disrupt athletic performance. Steel structures are designed with damping systems and rigid connections to minimize vibration, meeting criteria set by the International Organization for Standardization (ISO) for human comfort.

- Load Capacity for Multi-Use

Modern sports venues host diverse events—from sports games to concerts and trade shows—requiring steel structures to support varied loads. Steel beams and roofs are engineered to accommodate stage equipment (up to 50 tons), concert lighting rigs, and temporary seating, with additional capacity for future upgrades.

- Fire Safety

Sports venues must comply with strict fire codes to protect large crowds. Steel components are protected with intumescent paint or fire-rated encasements, ensuring they maintain structural integrity for 2–4 hours during a fire, as specified by the International Building Code (IBC).

Iconic Case Studies

- Beijing National Stadium (Bird’s Nest): The 2008 Olympic flagship venue uses 42,000 tons of Q460 high-strength steel to form its interwoven space grid structure. The roof spans 333 meters, supporting 80,000 seats and withstanding magnitude 8 earthquakes. Its iconic design has made it a global symbol of sports architecture.

- Mercedes-Benz Stadium (Atlanta): Home to the NFL’s Falcons, this stadium features a retractable steel roof with eight petal-shaped sections (each 70 meters wide). The steel structure weighs 3,500 tons, opens/closes in 60 minutes, and supports a 1,100-ton LED scoreboard—the largest in sports.

- London Aquatics Centre: Designed for the 2012 Olympics, this venue uses a steel space frame roof spanning 160 meters, supported by two concrete towers. The steel structure weighs just 1,800 tons, creating a lightweight, elegant form that complements the aquatic environment.

Sustainability and Future Trends

Modern sports venues prioritize sustainability, and steel structures contribute significantly to these goals: steel is 100% recyclable (the Bird’s Nest used 25% recycled steel), prefabrication minimizes on-site waste (by 70% compared to concrete), and steel roofs support rooftop PV systems (the Amsterdam Johan Cruijff Arena’s steel roof hosts 4,200 solar panels, generating 1.1 GWh annually). Future trends include smart steel structures with embedded sensors to monitor structural health, and modular steel systems that enable venue expansion or repurposing after major events (e.g., downsizing Olympic stadiums for post-event community use).

Conclusion

Steel structures have redefined the possibilities of sports venue architecture, merging unmatched span capability, structural resilience, and design flexibility to create venues that inspire athletes and delight spectators. From the grandeur of Olympic stadiums to the intimacy of indoor arenas, steel delivers the performance, durability, and efficiency required to host world-class sports events. As sports venues evolve to meet the demands of multi-use functionality, sustainability, and smart technology, steel will remain at the forefront, enabling innovative designs that balance engineering excellence with the passion of sports. In doing so, steel structures will continue to shape the iconic sports landmarks of the future, connecting communities through the power of live competition.