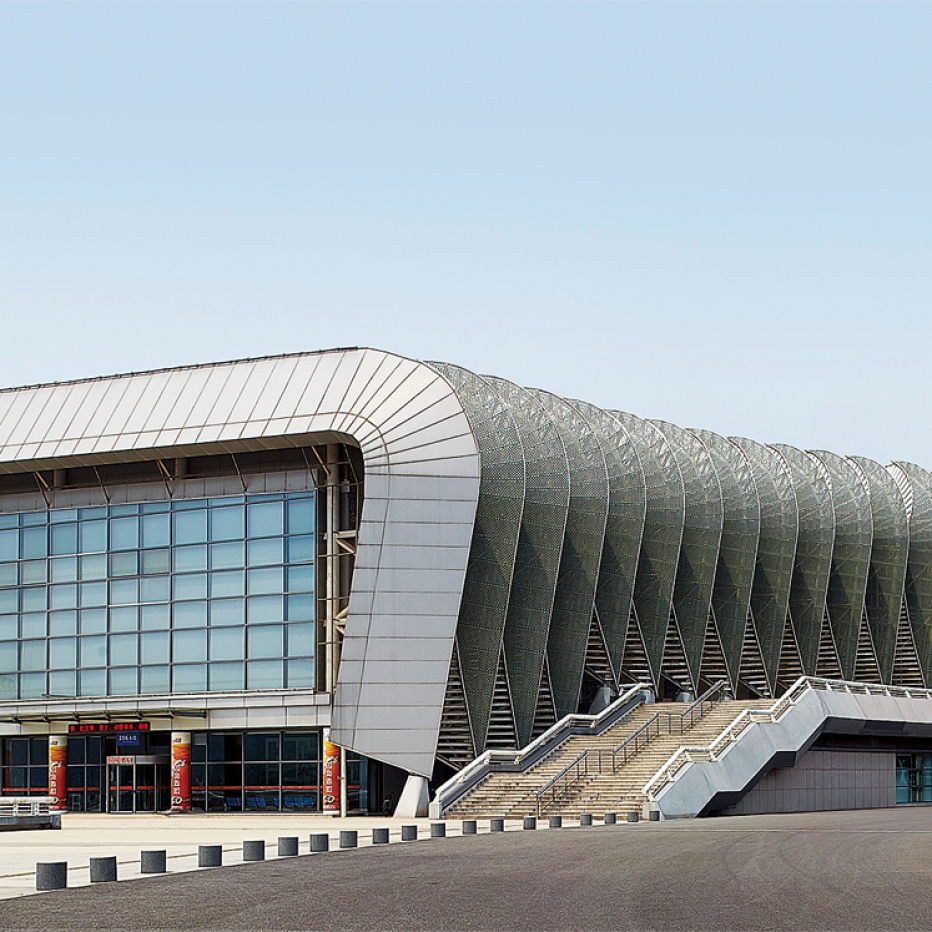

A Robust and Efficient Hub for Modern Manufacturing

An industrial workshop is a specialized and versatile facility engineered to support a wide spectrum of manufacturing, assembly, processing, and storage operations.

Designed with a focus on structural integrity, operational efficiency, and adaptability, modern industrial workshops integrate advanced structural systems, intelligent equipment, and human-centric layouts to meet the rigorous demands of contemporary industrial production. Unlike conventional warehouses or small-scale workshops, they are tailored to accommodate heavy machinery, high-volume production lines, and complex logistical workflows, serving as the core operational hub for industries ranging from automotive and aerospace to electronics and heavy machinery.

Core Design Principles: Balancing Strength and Functionality

The design of industrial workshops adheres to three fundamental principles that ensure their reliability and practicality: structural robustness, spatial flexibility, and operational safety. These principles guide every aspect of the facility, from foundation construction to roof design, ensuring it can withstand the unique stresses of industrial use while supporting evolving production needs.

Structural robustness is prioritized to handle heavy loads—including the weight of industrial machinery (such as CNC machines, stamping presses, and assembly robots), raw material stockpiles, and finished goods. The foundation is typically reinforced with deep piles or raft foundations to distribute concentrated loads evenly, preventing settlement or structural deformation. Spatial flexibility is achieved through modular design, allowing production lines to be reconfigured quickly as manufacturing processes evolve. Operational safety is embedded in features such as emergency exit routes, fire suppression systems, and anti-slip flooring, ensuring compliance with international industrial safety standards (e.g., OSHA, ISO 45001).

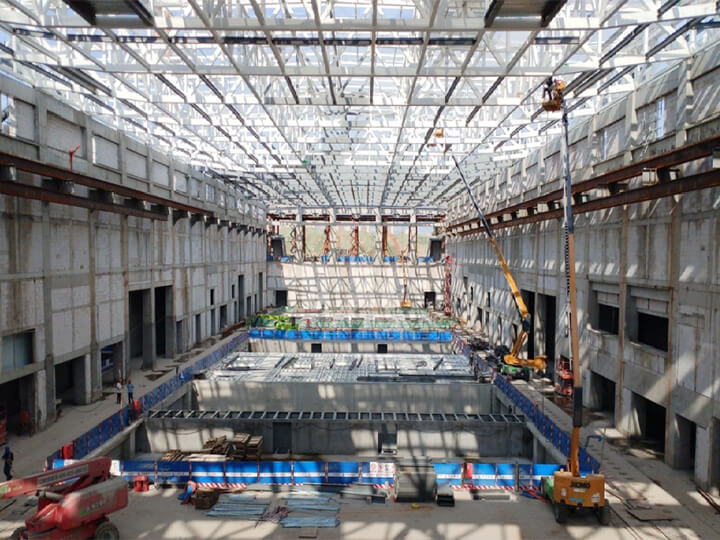

Structural Systems: The Backbone of Industrial Performance

Modern industrial workshops primarily adopt steel-based structural systems, which offer superior strength-to-weight ratios and large-span capabilities compared to traditional concrete structures. The most commonly used systems include:

- Steel Portal Frames: The most widely applied system for workshops with spans between 15m and 40m. Composed of steel columns and rafters connected at rigid joints, portal frames provide clear internal spaces with minimal supporting columns, facilitating the placement of large machinery and unobstructed workflow. They are cost-effective and quick to construct, making them ideal for medium-scale manufacturing facilities.

- Steel Space Grid Structures: Preferred for large-span workshops (spans exceeding 40m) or those requiring overhead cranes with high lifting capacities. The three-dimensional grid design distributes loads evenly across the entire structure, enabling it to support heavy crane systems (up to 500 tons) and large-scale production lines. This system is commonly used in automotive assembly plants and heavy machinery manufacturing facilities.

- Hybrid Steel-Concrete Structures: Utilized for workshops with mixed requirements, such as combining heavy-duty production areas with office or R&D spaces. Concrete is used for load-bearing foundations and lower floors, while steel structures form the upper framework and roof, balancing cost efficiency and structural performance.

All structural components undergo anti-corrosion treatments (hot-dip galvanizing or epoxy coating) to withstand industrial fumes, humidity, and chemical exposure, ensuring a service life of 50 years or more.

Key Facilities & Equipment Integration

A high-performance industrial workshop is equipped with a range of specialized facilities and systems that enhance productivity and operational reliability. These include:

- Logistical Support Systems: Overhead cranes (single-girder, double-girder, or gantry cranes) for vertical and horizontal movement of heavy components; conveyor belts and automated guided vehicles (AGVs) for seamless material transfer between production stations; and loading docks with hydraulic levelers for efficient truck loading/unloading.

- Environmental Control Systems: Ventilation systems (natural or mechanical) to remove industrial dust, fumes, and heat; heating, ventilation, and air conditioning (HVAC) systems for temperature-sensitive production processes (e.g., electronics manufacturing); and dust collection systems for metalworking or powder processing workshops.

- Power & Utility Infrastructure: High-capacity electrical distribution systems (380V/415V three-phase power) to support industrial machinery; backup generators to prevent production interruptions; compressed air systems for pneumatic tools; and water supply/drainage systems for cooling and cleaning processes.

- Intelligent Management Systems: Industrial internet of things (IIoT) sensors for real-time monitoring of machinery performance and environmental conditions; video surveillance and access control systems for security; and building management systems (BMS) to optimize energy consumption and facility maintenance.

Customization for Industry-Specific Needs

Industrial workshops are highly customizable to adapt to the unique requirements of different industries:

- Automotive Manufacturing: Features high-span steel space grid structures to accommodate assembly lines, robotic workstations, and overhead cranes. Floors are reinforced to support vehicle weight and equipped with anti-static coatings. Specialized ventilation systems remove paint fumes from the finishing area.

- Electronics Production: Cleanroom environments with controlled temperature (20-24℃) and humidity (45%-60%), HEPA filtration systems to remove particulate matter, and anti-static flooring to protect sensitive components. The structure is designed to minimize vibration, ensuring precision in microelectronics assembly.

- Heavy Machinery Manufacturing: Incorporates extra-strong foundations and overhead cranes with high lifting capacities (200-500 tons). The workshop is equipped with large roll-up doors for the entry/exit of oversized machinery and reinforced flooring for welding and forging operations.

- Food Processing: Features stainless steel wall panels and floors for easy cleaning, waterproofing systems to prevent moisture buildup, and temperature-controlled zones (refrigeration or freezing) for food storage and processing. The structure is designed to comply with food safety standards (e.g., FDA, HACCP).

Sustainability & Energy Efficiency Modern industrial workshops increasingly prioritize sustainability to reduce environmental impact and operational costs. Key green features include:

Roof-mounted photovoltaic (PV) systems to generate clean energy, reducing reliance on grid power.Energy-efficient LED lighting with motion sensors to minimize electricity consumption.Rainwater harvesting systems for cleaning and cooling processes, reducing water usage.Recyclable materials (e.g., steel structures) and modular design to facilitate future expansion or repurposing.These features not only lower the workshop’s carbon footprint but also qualify it for green building certifications (e.g., LEED, BREEAM), enhancing the enterprise’s environmental reputation.

Conclusion

An industrial workshop is more than just a production space—it is a integrated system that combines structural strength, advanced facilities, and intelligent management to drive manufacturing efficiency and reliability. From the choice of structural materials to the integration of specialized equipment, every aspect is designed to meet the unique needs of the industry it serves. As manufacturing technologies evolve toward automation and intelligence, modern industrial workshops will continue to adapt, incorporating new systems and designs to remain the backbone of global industrial production.