Exhibition Halls

Exhibition halls—encompassing trade show centers, art galleries, museum exhibition spaces, and convention venues

Exhibition halls—encompassing trade show centers, art galleries, museum exhibition spaces, and convention venues—demand architectural solutions that prioritize unobstructed floor areas, versatile layouts, and robust load-bearing capacity to accommodate diverse exhibits, from delicate artworks and interactive installations to heavy industrial machinery. Steel structures have emerged as the definitive choice for such facilities, leveraging their exceptional span capabilities, structural adaptability, and modular design to create spaces that balance functionality with architectural appeal. From the column-free halls of international trade centers to the lightweight roofs of art galleries, steel forms the structural foundation that enables exhibitions to evolve, engage, and inspire visitors.

Core Application Forms in Exhibition Halls

Steel structures adapt seamlessly to the varied needs of exhibition spaces, with configurations tailored to exhibit types, visitor flow, and architectural vision. Their flexibility ensures optimal performance whether for large-scale trade shows or intimate art exhibitions.

1. Main Exhibition Hall Structures: Column-Free Flexibility

The primary requirement for exhibition halls is unobstructed floor space to allow custom booth layouts, large exhibits, and smooth visitor circulation. Steel systems excel in delivering this through:

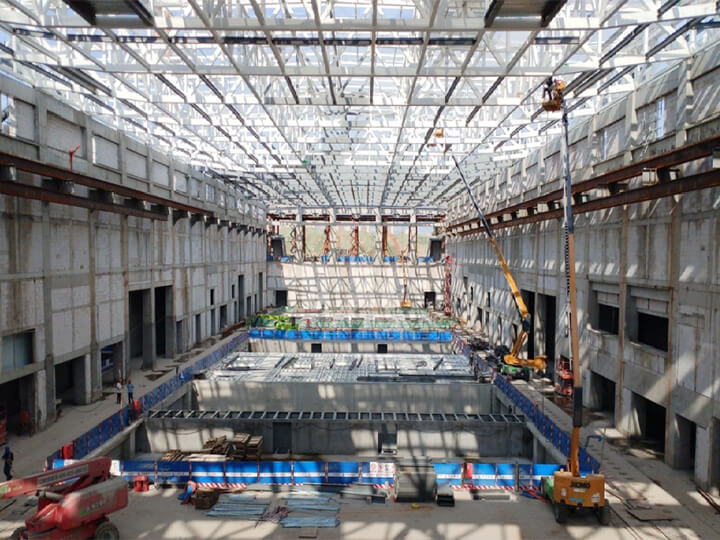

- Steel Space Grid/Latticed Shells: The most widely used system for large exhibition halls, these three-dimensional networks of steel tubes (circular or square) form lightweight yet rigid roof structures capable of spans up to 150 meters. The Shanghai National Exhibition and Convention Center uses a steel space grid roof to cover its 50,000-square-meter main hall, creating a completely column-free area that can host 10,000+ square meters of industrial exhibits.

- Steel Truss Systems: For mid-sized exhibition halls (10,000–30,000 square meters), parallel steel trusses—spaced 6–12 meters apart—provide a cost-effective solution. These trusses span 30–80 meters, supporting roof loads while leaving the floor area clear. The Hannover Messe Exhibition Center in Germany employs steel trusses in its modular halls, enabling quick reconfiguration for different trade show themes.

- Steel Portal Frames with Large Spans: Ideal for single-story exhibition pavilions or annex halls, steel portal frames (composed of steel columns and rafters) achieve spans of 20–40 meters. They are often used for temporary or specialized exhibition spaces, such as outdoor exhibition areas or seasonal trade show extensions.

2. Interior and Partition Structures: Modular Adaptability

Exhibition halls require frequent reconfiguration to accommodate different exhibit sizes and event formats. Steel structures enable this adaptability through:

- Light Steel Framing (LSF) Partitions: Cold-formed steel studs and tracks form non-load-bearing interior partitions that can be quickly installed, disassembled, and reused. These partitions divide large halls into smaller, themed spaces (e.g., product-specific zones at trade shows) without damaging the main structure, reducing setup time by 40% compared to traditional masonry partitions.

- Steel Mezzanines: For maximizing usable space in high-ceiling exhibition halls, steel mezzanines (supported by steel columns and beams) create upper-level areas for offices, VIP lounges, or small-scale exhibits. The mezzanines are designed to be modular, allowing for adjustments to size and load capacity based on event needs.

- Exhibit Support Structures: Steel framing provides custom support for specialized exhibits, including hanging installations (via steel cables and brackets), interactive displays (via rigid steel frames), and heavy machinery (via reinforced steel platforms). These structures are engineered to meet specific load requirements, from 50 kg for artworks to 50 tons for industrial equipment.

3. Specialized Exhibition Components

Steel structures also enhance the functionality and aesthetics of specialized exhibition elements, addressing unique demands:

- Glass Curtain Wall Frames: Steel framing supports large glass curtain walls in exhibition halls, creating transparent facades that showcase exhibits to passersby and flood interior spaces with natural light. The steel frames’ high strength-to-weight ratio enables expansive glass panels (up to 5m x 3m) without compromising structural integrity.

- Roof Glazing Support: Steel space grids or trusses support roof glazing (glass or ETFE panels) in atriums and light wells, ensuring even natural lighting across exhibition spaces—critical for art galleries and museum exhibits that require controlled illumination.

- Loading Dock and Logistics Structures: Steel portal frames and beams form the backbone of exhibition hall loading docks, supporting heavy-duty doors, ramps, and overhead cranes (10–20 tons) for moving large exhibits. The steel structures are designed to withstand frequent use by trucks and forklifts.

Key Advantages of Steel Structures for Exhibition Halls

Steel’s dominance in exhibition hall construction stems from its alignment with the core priorities of these facilities: flexibility, space optimization, and adaptability to changing exhibition needs.

- Ultra-Large Span Capability: Maximizing Usable Space

Exhibition halls’ value lies in their ability to accommodate diverse exhibits and layouts, which requires spans far beyond the capabilities of concrete. Steel space grids and trusses routinely achieve spans of 50–150 meters without intermediate columns, eliminating barriers to exhibit placement and visitor flow. For example, the Beijing National Convention Center’s main exhibition hall uses a steel space grid with a 120-meter span, allowing for the installation of full-scale aircraft and industrial turbines during trade shows.

- High Load-Bearing Versatility: Supporting Diverse Exhibits

Exhibition halls must support a wide range of loads—from 2–3 kPa for art displays and booths to 10–20 kPa for heavy machinery and industrial exhibits. Steel beams and floors are engineered to handle these variable loads, with additional reinforcement options (e.g., steel plate overlays) for specialized events. Steel’s ductility also ensures that loads are distributed evenly, preventing localized stress that could damage exhibits or the structure.

- Rapid Construction and Modularity: Accelerating Venue Readiness

Exhibition halls often face tight construction timelines to meet trade show schedules or museum opening dates. Steel components are prefabricated in factories with precision (CNC cutting, automated welding) and assembled on-site using bolted connections, reducing construction time by 30–50% compared to concrete. Modular steel systems also enable phased expansion—critical for exhibition centers growing to meet demand, such as the expansion of the Frankfurt Messe, which added 20,000 square meters of steel-framed exhibition space in just 18 months.

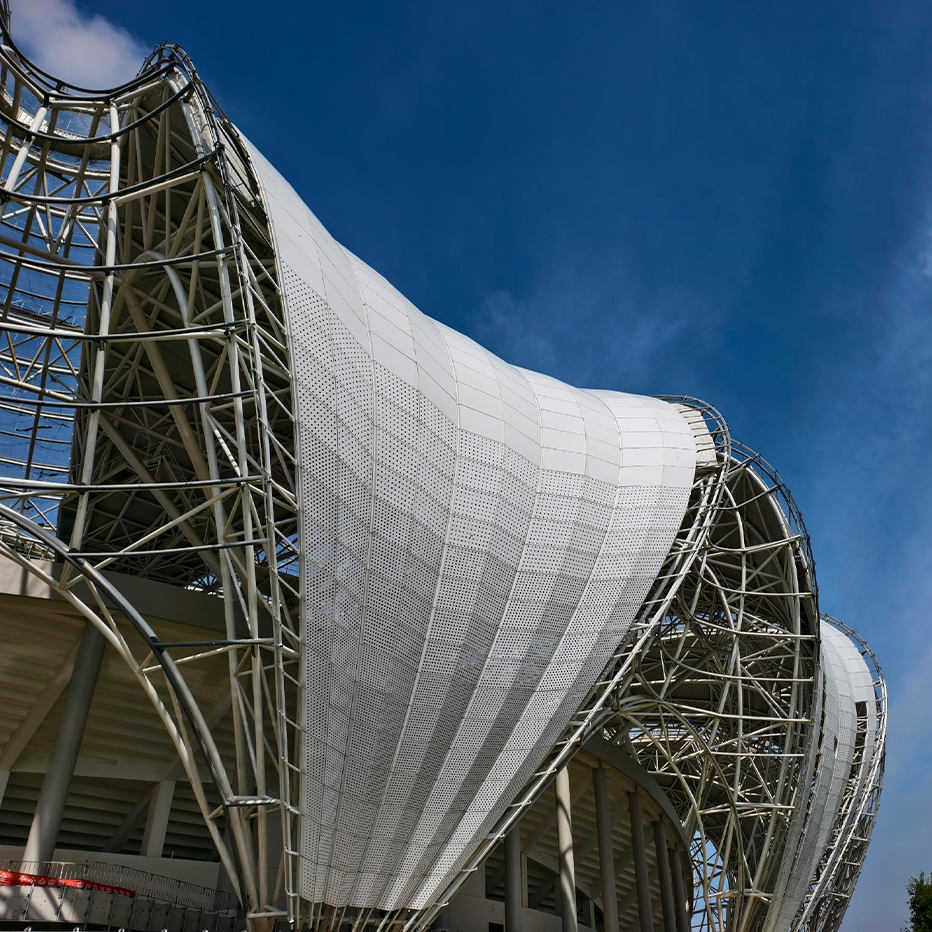

- Architectural Flexibility: Merging Function with Aesthetics

Exhibition halls often serve as cultural or commercial landmarks, and steel’s malleability enables architects to create distinctive designs. Steel can be left exposed (with a protective finish) for an industrial-chic aesthetic in contemporary art galleries, or concealed behind cladding for a sleek, minimalist look in high-end convention centers. Its ability to support large glass panels and lightweight roofing materials (e.g., ETFE) also creates bright, airy spaces that enhance the visitor experience.

- Durability and Low Maintenance: Ensuring Long-Term Reliability

Exhibition halls experience high traffic, frequent setup/teardown of exhibits, and exposure to varied environmental conditions (e.g., humidity for art exhibits, dust for industrial shows). Steel structures—treated with hot-dip galvanizing (zinc layer thickness ≥85μm), epoxy coating, or weathering steel—resist corrosion, wear, and pest damage, ensuring a service life of 60–100 years. Unlike concrete, steel requires minimal maintenance: annual inspections and occasional touch-ups to coatings are sufficient, reducing long-term operational costs for venue operators.

Critical Design Considerations for Exhibition Hall Steel Structures

To maximize steel’s benefits in exhibition spaces, engineers and architects address specialized challenges related to exhibit safety, visitor comfort, and operational efficiency:

- Lighting and HVAC Integration

Exhibition halls require sophisticated lighting (for exhibits) and HVAC systems (for visitor comfort). Steel roof structures are designed with integrated attachment points for overhead lighting rigs, spotlights, and HVAC ducts, eliminating the need for unsightly supports that would disrupt exhibit layouts. Steel space grids, in particular, provide a flexible framework for suspending these systems at varying heights.

- Acoustic Performance

Large exhibition halls can suffer from poor acoustics, which hinders communication at trade shows and distracts from art exhibits. Steel structures address this through composite steel-concrete floors (which reduce impact noise) and acoustic insulation integrated into steel roof and wall systems. Steel stud partitions with sound-damping materials also minimize noise transfer between divided exhibition spaces.

- Fire Safety

Exhibition halls, with their large visitor capacity and varied exhibits (some of which may be flammable), require strict fire compliance. Steel components are protected with intumescent paint or fire-rated encasements, ensuring they maintain structural integrity for 2–4 hours during a fire, as specified by the International Building Code (IBC). Steel’s non-combustibility also reduces the risk of fire spread compared to wooden structures.

- Floor Flatness and Load Distribution

Exhibits such as heavy machinery or precision displays require extremely flat floors to prevent instability. Steel-framed floors, with their rigid construction and precise leveling, meet the strict flatness standards (e.g., FF 50/FL 40 per ACI 117) required for such exhibits. Steel beams are also spaced to ensure even load distribution, preventing floor deflection that could damage delicate exhibits.

Iconic Case Studies

- Shanghai National Exhibition and Convention Center: One of the world’s largest exhibition venues, it uses 120,000 tons of steel to form its modular exhibition halls. The main hall features a steel space grid roof with a 150-meter span, supporting 100,000 square meters of column-free exhibition space that hosts international trade shows like the China International Import Expo.

- Tate Modern Switch House (London): A contemporary art gallery converted from a power station, it uses steel trusses and space grids to create flexible exhibition spaces. The steel structure enabled the addition of a 10-story extension with column-free galleries, supporting large-scale art installations and interactive exhibits.

- Hanover Messe Exhibition Center (Germany): A global hub for industrial trade shows, its modular exhibition halls use steel portal frames and trusses to achieve spans of 60 meters. The steel structure allows for quick reconfiguration—converting a hall from hosting automotive parts to heavy machinery in just 48 hours.

Sustainability and Future Trends

Modern exhibition halls prioritize sustainability to attract eco-conscious event organizers and meet green building certifications (LEED, BREEAM). Steel structures contribute to these goals in multiple ways: steel is 100% recyclable (the Tate Modern extension used 35% recycled steel), prefabrication minimizes on-site waste (by 70% compared to concrete), and steel roofs support rooftop PV systems (the Amsterdam RAI Exhibition and Convention Centre’s steel roof hosts 5,000 solar panels, generating 1.5 GWh annually). Future trends include smart steel structures with embedded sensors to monitor structural health and exhibit loads, and modular steel systems that enable exhibition halls to be repurposed for events like concerts or conferences—maximizing venue utilization.

Conclusion

Steel structures have become the backbone of modern exhibition hall architecture, offering a unique blend of space flexibility, load-bearing versatility, and architectural appeal that directly enhances a venue’s functionality and value. From column-free trade show halls to adaptive art galleries, steel addresses the core priorities of exhibition venue operators: maximizing usable space, supporting diverse exhibits, and reducing operational costs. As exhibition formats evolve—prioritizing interactivity, sustainability, and multi-use functionality—steel will remain at the forefront, enabling innovative designs that redefine how exhibits are displayed and experienced. Whether for a global trade show center or a local art gallery, steel structures deliver the adaptability, durability, and efficiency that drive successful exhibition spaces.