Steel Structures in Airport Buildings: Merging Strength, Spans, and Aesthetics

In modern airport architecture, steel structures have emerged as a dominant choice, defining the iconic silhouettes and functional cores of terminals, hangars, and auxiliary facilities worldwide.

Tailored to meet the unique demands of airport operations—including ultra-large spans, heavy load-bearing capacity, and rapid construction—steel systems integrate structural performance with architectural flexibility, supporting the seamless flow of millions of passengers and complex ground service operations. From the sweeping roofs of terminal buildings to the robust frameworks of aircraft hangars, steel structures form the backbone of airport infrastructure, balancing safety, efficiency, and visual impact.

Key Application Areas in Airport Buildings

Steel structures are strategically deployed across various airport components, each customized to address specific functional requirements. Their adaptability allows them to excel in both passenger-facing and operational zones, ensuring the airport’s overall functionality.

1. Terminal Buildings: The Architectural and Functional Heart

Terminal buildings demand structures that can create vast, unobstructed spaces while supporting complex loads (e.g., roofing systems, mechanical equipment, and passenger foot traffic)—a challenge steel structures meet with ease. Common applications include:

- Roof Structures: Steel space grid structures, trusses, and latticed shells are widely used for terminal roofs, enabling spans of 50–150 meters without intermediate columns. For example, the roof of Beijing Daxing International Airport’s main terminal uses a steel space grid with a maximum span of 180 meters, forming its distinctive “starfish” shape while covering 700,000 square meters of floor area. These systems support heavy roofing materials (e.g., glass, metal panels) and integrate seamlessly with natural lighting designs, reducing energy consumption.

- Facade Systems: Steel framing (e.g., hollow sections, I-beams) forms the backbone of terminal facades, supporting large-scale glass curtain walls that enhance transparency and passenger experience. The steel frames’ high strength-to-weight ratio allows for expansive glass panels, creating unobstructed views of the airfield while withstanding wind loads and seismic forces.

- Interior Structures: Light steel framing is used for mezzanines, passenger walkways, and service corridors, providing flexible interior layouts that can be reconfigured as terminal needs evolve (e.g., adding new check-in counters or retail spaces).

2. Aircraft Hangars: Robustness for Heavy-Duty Operations

Hangars require structures capable of accommodating large aircraft (e.g., Airbus A380, Boeing 747), supporting overhead cranes, and withstanding the weight of aircraft maintenance equipment. Steel portal frames and steel space trusses are the primary choices here, offering:

- Spans of 30–100 meters to fit full-size aircraft and maintenance teams.

- High load-bearing capacity to support overhead cranes (lifting capacities of 50–200 tons) used for engine removal and aircraft component replacement.

- Durability against aviation fuels, lubricants, and environmental factors (e.g., humidity, temperature fluctuations) when treated with anti-corrosive coatings (hot-dip galvanizing, epoxy).

- A typical large hangar uses steel portal frames with reinforced columns, ensuring the structure can withstand the dynamic loads of aircraft movement and maintenance operations.

3. Auxiliary Facilities: Efficiency for Supporting Operations

Steel structures also play a critical role in airport auxiliary facilities, where functionality and cost-efficiency are prioritized:

- Cargo Terminals: Steel racking systems and portal frame structures support high-density storage and heavy-duty forklift operations, with spans of 20–40 meters to facilitate cargo handling.

- Control Towers: Steel framing is used for the upper sections of control towers, offering lightweight yet rigid structures that support radar equipment and observation decks while minimizing wind-induced vibration.

- Ground Service Facilities: Steel-framed workshops, fuel storage buildings, and maintenance garages provide durable, cost-effective spaces for airport ground service operations.

Core Advantages of Steel Structures in Airport Applications

The widespread adoption of steel structures in airports stems from their unique combination of properties that align with the aviation industry’s rigorous demands:

1. Ultra-Large Span Capability

Airport terminals and hangars require vast, column-free spaces to ensure unobstructed passenger flow and aircraft movement. Steel space grid structures, trusses, and cable-stayed steel systems can achieve spans far exceeding those of concrete structures—up to 200 meters in specialized designs. This eliminates visual and physical barriers, enhancing the operational efficiency of terminals and hangars.

2. High Strength-to-Weight Ratio

Steel’s exceptional strength relative to its weight reduces the overall load on airport foundations, a critical advantage for large-scale projects built on varying soil conditions. For example, the steel roof structure of Singapore Changi Airport’s Jewel Terminal weighs 60% less than an equivalent concrete roof, minimizing foundation costs and construction complexity.

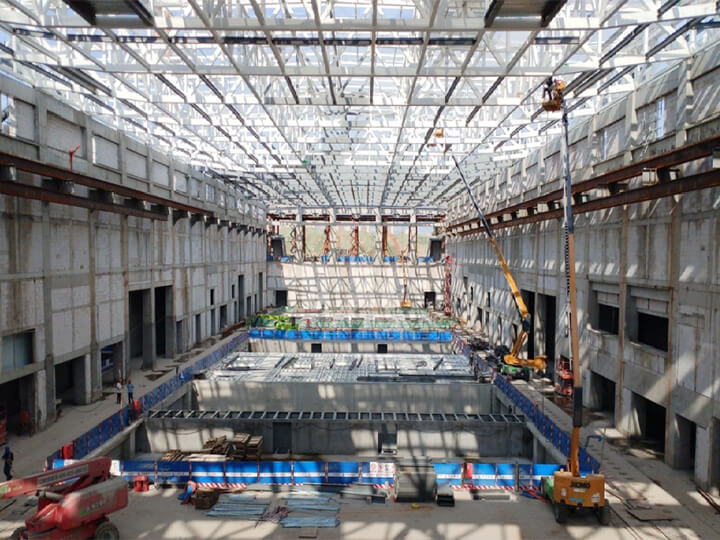

3. Rapid Construction and Modularity

Airports often operate 24/7, requiring construction and expansion projects to minimize disruption. Steel components are prefabricated in factories with high precision (CNC cutting, automated welding) and assembled on-site, reducing construction time by 30–50% compared to concrete. The modular design of steel systems also allows for phased expansion—critical for airports growing to meet passenger demand.

4. Durability and Low Maintenance

Airport structures must withstand harsh conditions, including aviation chemicals, saltwater (for coastal airports), and extreme weather. Steel treated with hot-dip galvanizing (zinc layer thickness ≥85μm) or epoxy coating resists corrosion, ensuring a service life of 50–100 years. Unlike concrete, steel requires minimal maintenance—annual inspections and occasional touch-ups to coatings are sufficient to preserve performance.

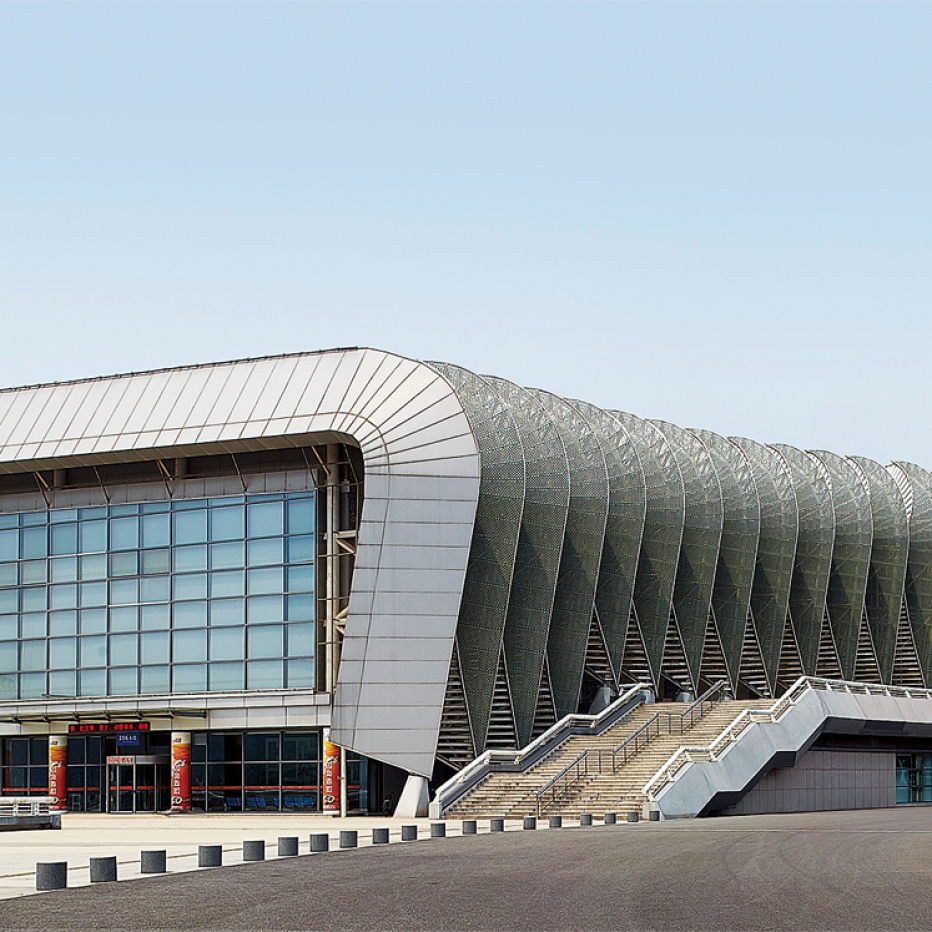

5. Architectural Flexibility

Steel’s malleability allows architects to create iconic, aerodynamic designs that reflect a city’s identity. From the curved steel roof of Dubai International Airport’s Terminal 3 to the angular steel frames of London Heathrow’s Terminal 5, steel structures enable bold architectural expressions while meeting functional requirements. They also integrate seamlessly with other materials (glass, stone, metal panels) to create visually striking and functional spaces.

Sustainability: Aligning with Green Airport Goals

As airports pursue carbon neutrality, steel structures contribute to sustainable design in multiple ways:

- Recyclability: Steel is 100% recyclable, with a recycling rate of over 90% in construction. Many airport steel projects use recycled steel, reducing embodied carbon by 40–50% compared to virgin steel.

- Energy Efficiency: Steel roof structures support lightweight, energy-efficient roofing materials (e.g., insulated metal panels) and solar PV systems. Copenhagen Airport’s terminal roof, for example, features a steel grid supporting 10,000 solar panels, generating 3.5 GWh of clean energy annually.

- Reduced Waste: Factory prefabrication minimizes on-site waste, a key advantage for airports aiming to reduce construction-related landfill usage.

Iconic Case Study: Beijing Daxing International Airport

A benchmark for steel structure application in airports, Beijing Daxing International Airport’s main terminal uses 50,000 tons of steel to form its “starfish”-shaped roof. The roof employs a steel space grid structure with 12 radial trusses, each spanning 180 meters, creating a column-free central hall of 190,000 square meters. The steel components were prefabricated in 12 factories across China and assembled on-site in just 18 months, demonstrating the efficiency of steel construction. The structure is designed to withstand typhoons (wind speeds up to 50 m/s) and magnitude 8 earthquakes, ensuring operational safety in extreme conditions.

Conclusion

Steel structures have become the backbone of modern airport architecture, combining strength, span capability, and flexibility to meet the unique demands of aviation operations. From terminal roofs that create vast, welcoming spaces to hangar frames that support heavy aircraft maintenance, steel systems deliver the performance, durability, and efficiency airports require. As the aviation industry evolves toward sustainability and automation, steel structures will continue to innovate—integrating with smart technologies (e.g., sensor-equipped steel components for structural health monitoring) and green materials to create airports that are safer, more efficient, and environmentally friendly. In doing so, they will remain a critical component in shaping the future of global air travel hubs.